Why the 90 Micron Dry Sift Screen is Crucial in Pharmaceutical Applications

In pharmaceutical applications, precision and consistency are paramount. The 90 micron dry sift screen plays a vital role in achieving these standards, especially when it comes to the production of fine powders and granules. This specific screen size is often used to ensure that particles meet the stringent size requirements necessary for effective drug formulation.

By utilizing a 90 micron dry sift screen, pharmaceutical labs can achieve uniform particle size distribution, which directly impacts the dissolution rate and bioavailability of the drugs produced. For instance, if the particles are too large, they may not dissolve properly, leading to ineffective medication. On the other hand, particles that are too fine may cause issues like clumping or segregation. Therefore, the 90 micron screen strikes a balance, ensuring that the active pharmaceutical ingredients (APIs) are consistent in size, leading to reliable and effective final products.

Moreover, the use of a 90 micron dry sift screen helps in maintaining the purity of the product by effectively separating impurities or oversized particles. This not only enhances the quality of the pharmaceutical products but also ensures compliance with regulatory standards, making it an essential tool in any pharmaceutical lab.

Optimizing Pharmaceutical Production with Multi-Deck Vibratory Sifters and Rotary Lab Sifters

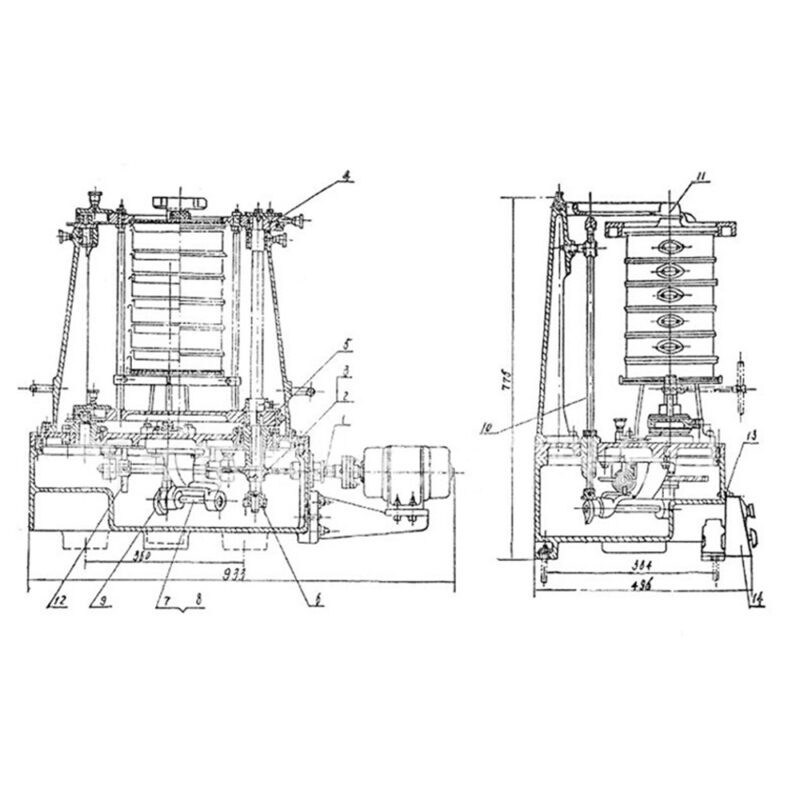

In the competitive world of pharmaceutical manufacturing, optimizing production processes is key to maintaining efficiency and profitability. Multi-deck vibratory sifters, along with rotary lab sifters, offer advanced solutions for achieving this optimization. These machines are designed to handle multiple screening levels simultaneously, allowing for the precise separation of different particle sizes in a single pass.

Multi-deck vibratory sifters are particularly useful in scenarios where multiple particle size fractions are required. For example, in tablet production, different particle sizes may be needed for various layers or coatings of the tablet. By using a multi-deck sifter, these different sizes can be accurately separated and collected, reducing the need for multiple machines and streamlining the production process.

Rotary lab sifters complement this process by providing a gentle, yet effective, method of screening, particularly for delicate materials that may be damaged by more aggressive vibration. These sifters can be used in conjunction with multi-deck vibratory sifters to ensure that all particles are screened to the desired size and quality, thus optimizing the overall production process.

The combination of these two types of sifters not only increases efficiency but also enhances product consistency and quality, which is critical in pharmaceutical manufacturing. By reducing the risk of cross-contamination and ensuring that all particles are within the required size range, these sifters play a crucial role in maintaining the integrity of the final product.

The Importance of Fine Mesh Screens in Pharmaceutical Sieve Analysis

Fine mesh screens are integral to the sieve analysis process in pharmaceutical labs, as they ensure the accurate classification of particles by size. This is particularly important when dealing with fine powders, where even the slightest variation in particle size can affect the efficacy of the drug. Fine mesh screens, such as those used in multi-deck vibratory sifters, provide the precision needed to ensure that all particles meet the required specifications.

The importance of fine mesh screens extends beyond just the size of the particles; they also contribute to the overall efficiency of the screening process. Finer screens can process more material at once, leading to faster throughput and reduced processing times. This is particularly beneficial in high-volume pharmaceutical production environments, where time is of the essence.

Additionally, fine mesh screens help in the detection of any foreign particles or contaminants that may have been introduced during the production process. By capturing these unwanted materials, fine mesh screens play a crucial role in maintaining the purity and quality of the pharmaceutical products.

In summary, fine mesh screens are essential for ensuring the accuracy and efficiency of sieve analysis in pharmaceutical labs. Their ability to provide precise particle classification, coupled with their role in maintaining product purity, makes them indispensable tools in the pharmaceutical industry.