1. Understanding the Key Components of Vibrating Screens for South African Industries

Vibrating screens are essential in various industries, especially in South Africa’s mining, construction, and manufacturing sectors. Understanding the key components of a vibrating screen helps businesses make informed decisions about which screen to choose for their specific needs.

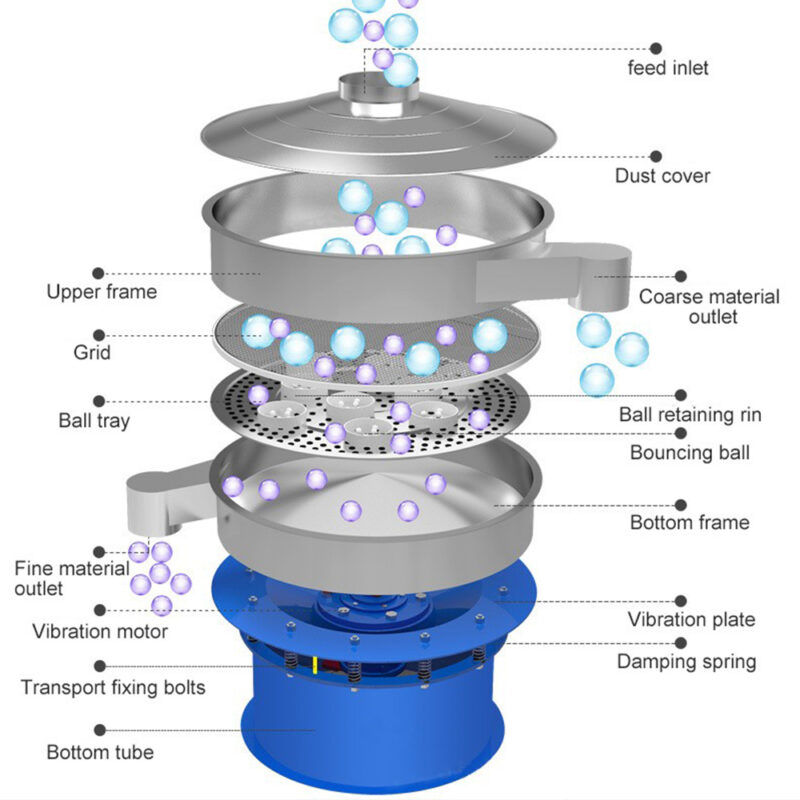

- Motors: The motor is the heart of the vibrating screen, providing the necessary power to create vibration. The motor’s size and type will depend on the load capacity and the type of materials being processed. In South Africa, industries like mining, where large volumes of material are handled, often require motors with higher horsepower to ensure efficient performance.

- Springs: Springs serve to absorb the vibrating forces and prevent excessive movement of the screen body. In South African industries, where machines run for extended hours, durable springs made from materials like steel or polyurethane are vital for preventing wear and ensuring long-term reliability.

- Screen Mesh or Sieves: The screen mesh is a crucial component as it determines the size of the particles that will pass through. For mining industries in South Africa, having the right mesh size is critical to ensuring effective material separation and meeting industry standards for particle size distribution.

- Frame: The frame of the vibrating screen holds the mesh and motor in place. The material and design of the frame must support the screen’s movement and provide stability during operation. South African industries benefit from robust frame designs that can withstand the tough conditions of mining and mineral processing.

- Bearings: Bearings are used to support the movement of the vibrating screen and reduce friction between moving parts. Reliable bearings are essential for reducing downtime and maintenance costs. In South Africa’s demanding industries, high-quality bearings are a must for ensuring continuous operation.

By understanding these components, South African industries can choose the right vibrating screen tailored to their needs, improving productivity and minimizing operational issues.

2. How Vibrating Screens Are Used in Coal Sieve Analysis for South African Mining

Vibrating screens play a pivotal role in coal sieve analysis, a process widely used in South Africa’s mining sector. Coal sieve analysis involves separating coal into various particle sizes to determine its quality, consistency, and suitability for various industrial uses.

- The Importance of Sieve Analysis: In South African coal mining, accurate sieve analysis ensures that the right coal particles are extracted for specific uses like energy generation or export. Different mesh sizes are used to separate coal into fine, medium, and coarse particles, making it essential to have a reliable vibrating screen to carry out the separation process.

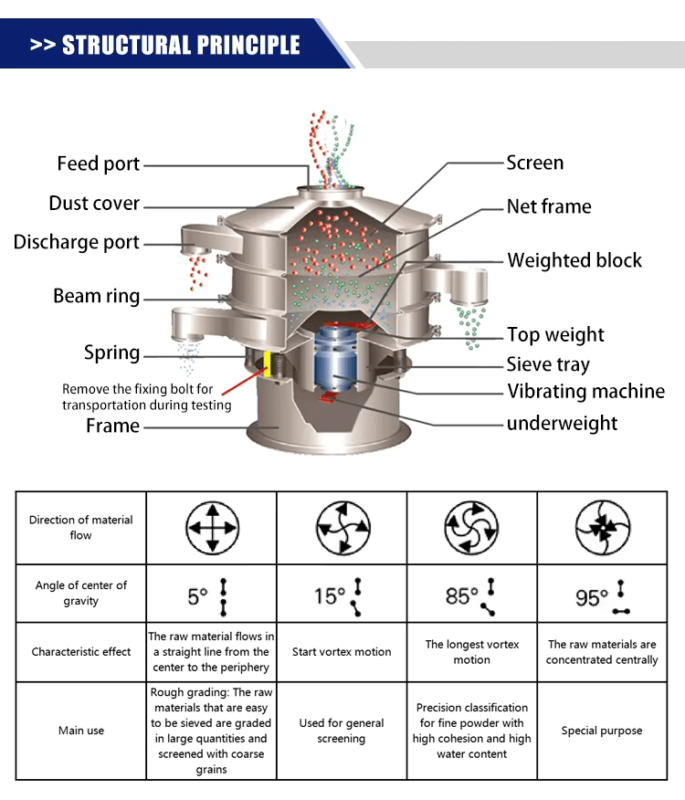

- How Vibrating Screens Work in Coal Sieve Analysis: Vibrating screens are designed to effectively sort coal particles by size. The screen’s vibration facilitates the movement of particles through the mesh, ensuring that finer particles pass through while larger particles remain on top. This allows miners to collect and categorize coal based on particle size, ensuring that each grade of coal is used appropriately.

- Enhanced Efficiency and Accuracy: In South African mining, accurate and efficient sieve analysis is critical for maintaining the quality and consistency of coal output. Vibrating screens ensure that the separation process is performed quickly and precisely, allowing for higher production volumes and less waste.

- Durability and Reliability: The tough conditions of coal mining require vibrating screens that can withstand abrasive materials and constant vibration. South African industries rely on heavy-duty, high-quality vibrating screens to ensure that sieve analysis is conducted without interruptions, improving operational efficiency.

In summary, vibrating screens in coal sieve analysis are indispensable for achieving precise material separation, reducing operational costs, and ensuring that coal meets the required specifications for various applications.

3. Integrating Rotary Sand Sieving Machines into South Africa’s Sand Mining Operations

Sand mining in South Africa, particularly along the country’s vast coastlines and in construction-heavy regions, requires specialized equipment to efficiently separate fine and coarse sand particles. Rotary sand sieving machines, in combination with vibrating screens, are crucial in optimizing sand mining operations.

- Rotary Sand Sieving Machines vs. Vibrating Screens: While vibrating screens excel at separating materials based on size, rotary sand sieving machines are ideal for handling larger volumes of sand. The rotary motion allows for thorough separation, making them ideal for use in sand mining, where both fine and coarse particles need to be separated efficiently. These machines can handle high volumes of material with minimal downtime.

- Improved Efficiency in Sand Mining: Integrating rotary sand sieving machines into sand mining operations enhances the efficiency of the separation process. South African mining companies benefit from the ability to screen large amounts of sand quickly, reducing the need for manual sorting and increasing production rates.

- Customization for Specific Applications: Rotary sand sieving machines can be customized to suit different sand mining requirements. The mesh size, drum rotation speed, and capacity can all be adjusted to match the type of sand being processed. For example, construction-grade sand requires finer sieving, while industrial sand may need a more robust sieving process. This adaptability makes rotary sand sieving machines highly suitable for South African sand mining operations, where different grades of sand are in demand.

- Cost Savings and Environmental Impact: By improving the efficiency of the sand screening process, rotary sand sieving machines help reduce operating costs in the long term. Additionally, they can contribute to more sustainable practices in the sand mining industry, as they minimize waste by ensuring that sand is properly sorted and screened. In South Africa, where environmental considerations are becoming more important, this is an added benefit.

Incorporating rotary sand sieving machines into South African sand mining operations allows for better material separation, higher production rates, and enhanced cost-effectiveness, making them an indispensable tool for modern sand mining.