Introduction: The Importance of Precision in Plastic Granule Production

In the plastic manufacturing industry, consistency and quality are non-negotiable. Whether the plastic granules are used for injection molding, extrusion, or compounding, their size, purity, and uniformity directly impact the final product’s strength, appearance, and functionality. Even minor variations in granule size or contamination can lead to production defects, material waste, and increased costs.

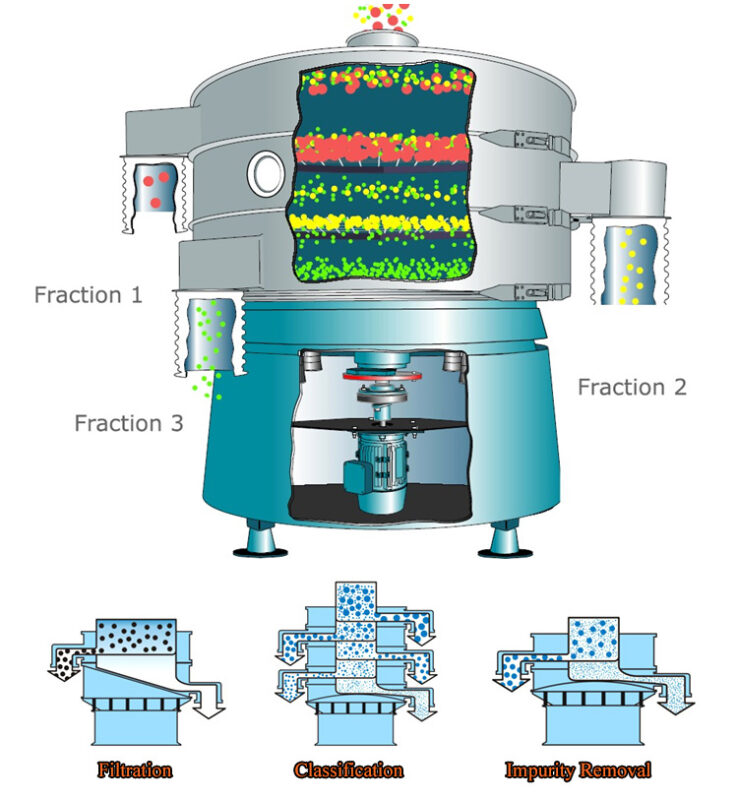

One of the most critical steps in plastic granule production is sieving—a process that ensures uniform particle size, removes impurities, and enhances production efficiency. Advanced sieving machines separate oversized particles, eliminate dust, and prevent contamination, making them indispensable for plastic manufacturers.

In this blog, we will analyze the four key reasons why sieving is essential for producing high-quality and consistent plastic granules, focusing on quality control, efficiency, material recovery, and industry compliance.

Segment 1: Achieving Uniform Particle Size for Superior Product Quality

Plastic granules serve as raw materials for injection molding, blow molding, extrusion, and 3D printing. The quality of these processes depends on consistent granule size and distribution. If the granules vary in size, manufacturers may face issues like:

- Uneven melting rates, leading to inconsistent product formation

- Clogging in feeders and hoppers, causing production delays

- Defective molded products due to irregular flow and compounding inconsistencies

Advanced vibratory sieving machines, ultrasonic sieves, and centrifugal sifters ensure precise size classification, effectively removing oversized or undersized granules. For example, in PET granule production, sieving helps eliminate fine dust and broken particles, ensuring a smooth flow during extrusion. Similarly, polypropylene (PP) granules need to be uniformly sized to maintain consistent wall thickness in molded parts.

By investing in high-performance sieving technology, manufacturers can maintain batch-to-batch consistency, ensuring that plastic granules meet customer specifications and industry standards.

Segment 2: Increasing Production Efficiency and Reducing Downtime

In plastic granule production, efficiency is key to maximizing output and minimizing costs. Manual sieving or outdated screening methods often lead to:

- Production slowdowns due to material buildup and clogging

- Frequent maintenance issues caused by inefficient separation

- Excessive labor costs from manual quality control

Modern automated sieving machines address these challenges by:

- Processing large volumes of granules with minimal human intervention

- Preventing sieve clogging with self-cleaning mesh technology

- Allowing continuous operation, reducing production halts

For example, a high-capacity vibratory sieve can process tons of polyethylene (PE) granules per hour, significantly improving production efficiency compared to manual or basic screening methods. Additionally, ultrasonic sieving technology prevents plastic granules from sticking together, ensuring smooth operation.

With automated sieving solutions, manufacturers can reduce downtime, labor costs, and material waste, making production more cost-effective and scalable.

Segment 3: Maximizing Material Recovery and Reducing Waste

Plastic granule manufacturers must optimize raw material utilization to remain cost-efficient and environmentally responsible. Traditional sieving methods often lead to:

- Loss of usable granules due to inefficient screening

- Accumulation of defective material, requiring costly reprocessing

- Wasted resources that could be reintegrated into the production cycle

Modern sieving machines offer precision screening that helps manufacturers:

- Recover usable granules, reducing raw material costs

- Separate defective particles efficiently, ensuring only high-quality granules enter production

- Reintroduce recovered material, reducing overall waste

For instance, in PVC granule processing, an advanced sieving machine can separate fine dust and oversized particles, allowing manufacturers to reprocess and reuse material instead of discarding it. Similarly, in recycled plastic granule production, precise sieving ensures that only high-quality granules are reintegrated into the manufacturing process, improving overall sustainability.

By minimizing material waste, companies can achieve higher profitability and contribute to environmental sustainability—a crucial factor in today’s competitive market.

Segment 4: Meeting Industry Standards and Regulatory Compliance

The plastic manufacturing industry is governed by strict quality and safety standards, especially for products used in food packaging, medical devices, and automotive components. Contaminants, irregular granules, or foreign particles can lead to non-compliance issues, resulting in:

- Rejected batches and financial losses

- Legal liabilities and fines for failing safety standards

- Damage to brand reputation and customer trust

Advanced sieving machines play a crucial role in ensuring compliance with industry regulations, such as:

- ISO 9001 for quality management systems

- FDA regulations for plastic granules used in food-grade packaging

- RoHS compliance for electrical and automotive plastic components

For example, in medical-grade plastic granule production, high-precision sieving eliminates contaminants, ensuring that materials meet strict hygiene and safety requirements. Similarly, for automotive plastic components, sieving guarantees that only high-performance granules are used, preventing defects in critical parts.

By integrating state-of-the-art sieving machines, manufacturers can maintain regulatory compliance, reduce product recalls, and build a reputation for reliability and excellence.

Conclusion: The Future of Plastic Granule Manufacturing with Sieving Technology

As plastic manufacturing continues to evolve, precision, efficiency, and sustainability remain top priorities. Sieving technology is no longer just an optional step—it is a necessity for ensuring high-quality and consistent plastic granules.

By adopting advanced sieving solutions, manufacturers can:

✅ Achieve uniform granule size, enhancing product performance

✅ Improve production efficiency, reducing downtime and labor costs

✅ Minimize waste and maximize material recovery, boosting profitability

✅ Ensure compliance with industry standards, avoiding legal risks and quality issues

The right sieving machine is an investment that offers long-term benefits, making plastic granule production more efficient, cost-effective, and environmentally sustainable.

Are you ready to upgrade your plastic granule sieving process? Explore the latest high-precision sieving machines and take your manufacturing to the next level! 🚀