Introduction: The Importance of Tea Purity in Thailand

Tea is a cornerstone of Thai culture, woven into the fabric of daily life, from refreshing iced teas to ceremonial brews. For Thailand to maintain its global reputation as a tea producer, ensuring the purity of its tea is paramount. Tea purity directly influences its quality, and for Thai tea producers, delivering a product that consistently meets global standards is critical. Purity affects not only the visual appeal but also the taste, aroma, and health benefits of the tea. The slightest impurity can degrade the overall experience and diminish consumer trust.

In Thailand’s tea industry, maintaining purity is essential for a variety of reasons. First, it directly impacts the quality of the end product. Secondly, a high level of purity is crucial for ensuring that the tea retains its characteristic flavor profile and nutritional benefits. Any contaminants, whether foreign particles, dust, or even damaged leaves, can disrupt the natural balance of flavor and aroma, leading to subpar tea. The Thai tea industry also faces specific challenges in achieving purity, such as the manual nature of sorting, the variability of raw materials, and inconsistent processing methods.

How Sieve Machines Contribute to Tea Purity in Thailand

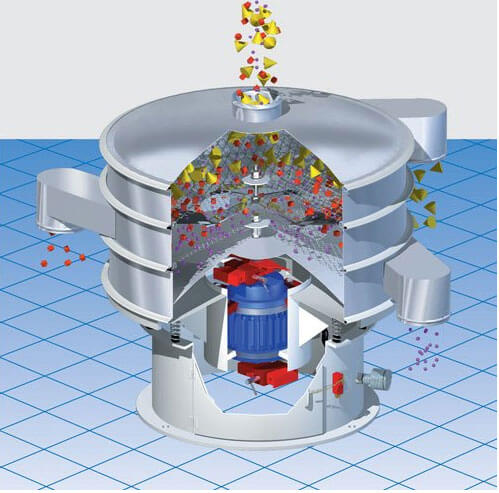

Sieve machines are at the forefront of enhancing tea purity, providing an efficient and effective solution to separate impurities from tea leaves. These machines work by employing a combination of vibration and mesh filtration to sort tea leaves, ensuring that only the highest-quality leaves make it into the final product. The vibration helps agitate the material, causing particles of different sizes to separate, while the mesh acts as a barrier to filter out any unwanted materials.

The mesh size is a critical aspect in optimizing tea leaf quality. By selecting the right mesh size, sieve machines can ensure that the right particles pass through while trapping contaminants, such as twigs, stems, and dust. The vibration frequency also plays a pivotal role, as different frequencies are better suited to different types of tea. Adjusting the vibration settings allows producers to fine-tune the sorting process for various tea varieties, ensuring consistency and uniformity in the product.

Furthermore, sieve machines help ensure that tea leaves are consistently graded, reducing the chances of blending different leaf grades and ensuring uniformity in the final product. This consistency is essential for meeting consumer expectations and maintaining a reliable brand image in the competitive tea market.

The Benefits of Sieve Machines for Tea Producers in Thailand

One of the key advantages of sieve machines is their ability to significantly boost efficiency in tea production. Traditional methods of tea sorting are often labor-intensive and time-consuming, leading to lower productivity. With sieve machines, the sorting process is automated, allowing tea producers to process larger volumes of tea leaves in less time. This increased throughput is crucial in meeting both local and international demand for high-quality tea.

Additionally, sieve machines help minimize contamination and ensure that the final product adheres to stringent quality standards. By effectively removing unwanted particles, they guarantee that the tea retains its purity. This not only improves the flavor and aroma of the tea but also enhances its marketability. Consumers today are more discerning, and maintaining a high-quality standard is essential for building consumer trust and loyalty.

Sieve machines also reduce waste and maximize yield. By accurately separating high-quality leaves from lower-quality ones, producers can ensure that only the best tea enters the market. This not only reduces the loss of valuable raw material but also contributes to more efficient use of resources, which is vital for the profitability of tea producers. In a competitive industry like tea production, this is an invaluable advantage.

Choosing the Right Sieve Machine for Thai Tea Production

When selecting a sieve machine for tea production, there are several factors to consider. One of the most important is the mesh size. Different tea types and processing goals require different mesh sizes, and the wrong mesh can lead to ineffective separation and compromised tea purity. Producers should carefully assess the type of tea they are working with—whether it’s green, black, or oolong—as each variety may require a different mesh configuration to achieve the desired quality.

Vibration frequency and amplitude are also crucial elements. The settings must be tailored to suit the characteristics of the tea being processed. Higher frequencies might be necessary for finer tea leaves, while lower frequencies might be better suited for coarser tea. Adjusting these settings ensures that the sieve machine performs optimally, providing the desired level of separation and purity.

Capacity is another key consideration. Tea production in Thailand can vary widely in scale, and the sieve machine selected must be able to handle the required volume without sacrificing performance. A machine with the right capacity will ensure that tea producers can meet their production demands without experiencing bottlenecks.

Finally, ensuring the longevity and efficiency of the sieve machine is essential. Tea producers should look for machines that are durable and easy to maintain. Regular maintenance is crucial to ensure long-term performance, and machine downtime due to maintenance issues can be costly. Choosing a sieve machine that is both reliable and easy to maintain will help keep operations running smoothly and consistently.

Conclusion: Elevating Thai Tea Quality with Sieve Machines

The use of sieve machines in tea production represents a significant leap forward in maintaining tea purity, enhancing efficiency, and ensuring consistent quality. For Thai tea producers, embracing this technology is not just an investment in better processing but also an investment in brand reputation and consumer satisfaction. With the ability to separate impurities, optimize particle size, and boost overall productivity, sieve machines are revolutionizing the way tea is processed in Thailand.

By selecting the right sieve machine for their specific needs, producers can ensure that their tea remains at the top of the market, satisfying the growing global demand for pure, high-quality tea. Whether it’s maintaining the traditional flavors of Thai tea or exploring new blends, the consistent quality enabled by sieve machines will help elevate the Thai tea industry to new heights.