Saffron, often referred to as “red gold,” is one of the most valuable spices in the world. In Oman, saffron cultivation and processing are gaining prominence due to increasing demand for high-purity, premium-grade saffron in global markets. To maintain top-tier quality standards, saffron producers must eliminate impurities and ensure uniform strand consistency.

Sieving machines play a crucial role in optimizing saffron processing by removing contaminants, classifying saffron threads, and maintaining product integrity. This blog explores how sieving machines help Omani saffron producers achieve unparalleled purity and consistency.

1. The Significance of Impurity Screening in Maintaining Saffron Purity

Saffron is a delicate spice derived from the stigma of the Crocus sativus flower. To maintain its high value, it must be carefully processed to remove impurities such as:

- Dust and debris from harvesting and drying

- Yellow and white saffron styles that reduce product quality

- Broken saffron threads that affect appearance and grading

- Foreign matter, including plant residue and tiny stones

Why Sieving Machines Are Essential for Saffron Purity:

- Precision Screening: High-quality sieving machines can efficiently separate pure saffron threads from unwanted materials without causing damage.

- Maintaining Grade Standards: Top-grade saffron (such as ISO Category I saffron) requires stringent impurity control. Sieving ensures only premium-quality strands are retained.

- Improving Market Value: Clean, uniform saffron strands fetch higher prices, making impurity screening a key step in boosting profitability.

By integrating commercial sieving technology, Omani saffron producers can ensure compliance with international standards while delivering the purest product to consumers.

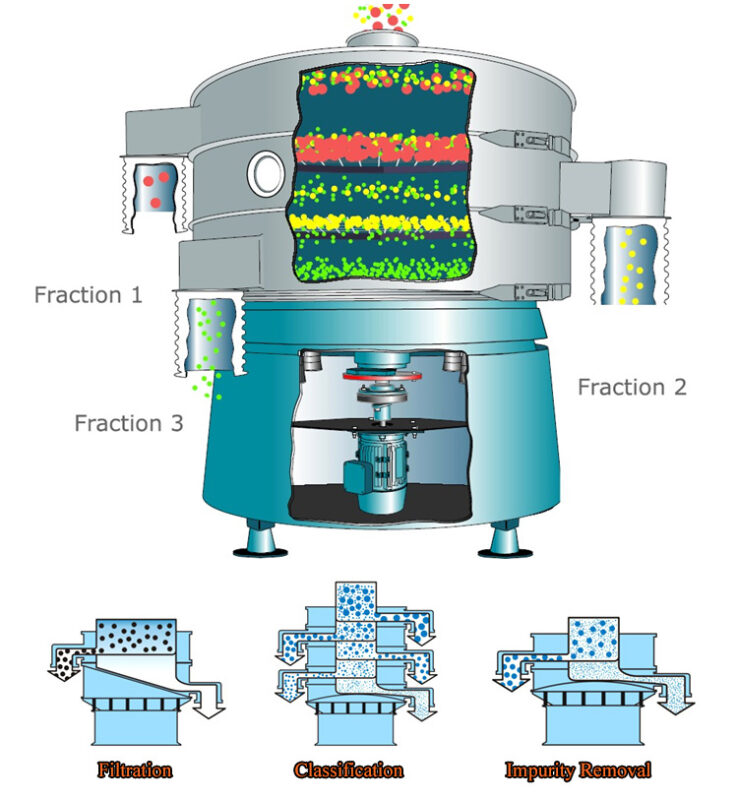

2. Choosing the Right Commercial Vibro Sifting Sieve for Saffron

Not all sieving machines are suitable for saffron processing. Since saffron threads are delicate, choosing the right commercial sieve is critical to avoid damage and maintain purity.

Key Features to Look for in a Saffron Sieving Machine:

- Vibration Control: Vibro sifting sieves with adjustable vibration intensity ensure gentle handling, preventing saffron strands from breaking.

- Multi-Layer Mesh System: A high-precision mesh system enables graded separation, allowing saffron to be classified into premium strands, smaller fragments, and rejected particles.

- Non-Contaminating Materials: Stainless steel sieving machines are ideal, as they prevent contamination and comply with food safety regulations.

- Efficient Dust Removal: Fine mesh sieving helps remove tiny dust particles and loose pollen, improving overall cleanliness.

- Customizable Mesh Sizes: Saffron producers should choose sieves with mesh sizes optimized for separating full saffron threads from smaller, lower-grade pieces.

Investing in high-quality vibro sifting sieves allows Omani saffron processors to enhance efficiency, reduce labor costs, and maintain saffron quality across large-scale production.

3. Integrating Sieving Equipment into Saffron Production Lines

For optimal results, sieving machines should be seamlessly incorporated into the saffron processing workflow. This ensures that the spice is efficiently cleaned, graded, and packaged without unnecessary manual handling.

Steps to Integrate Sieving Equipment into a Saffron Production Line:

- Pre-Sieving Stage – Removing Large Debris: Before drying, saffron threads can pass through an initial sieve to remove large contaminants such as flower petals and unwanted plant parts.

- Post-Drying Fine Sieving – Removing Dust and Broken Strands: After saffron is dried, fine-mesh sieves help eliminate dust, tiny fragments, and non-standard pieces.

- Size Grading and Sorting – Ensuring Uniformity: A multi-tier sieving system classifies saffron strands based on length and thickness, allowing producers to separate premium strands from lower-grade saffron.

- Final Quality Check – Optical Sorting & Sieving Combination: Some advanced processing lines combine vibro sieving with optical sorting technology to further refine the product.

Benefits of Fully Integrated Sieving in Saffron Processing:

- Faster Processing Speeds: Automated sieving reduces manual labor and speeds up the separation process, improving overall productivity.

- Higher Yield with Less Waste: Proper sieving ensures more usable saffron is retained, reducing material loss.

- Consistent Product Quality: Uniformly sized saffron threads enhance the appearance and market appeal of the final product.

By implementing automated sieving solutions, Omani saffron producers can scale their operations while maintaining exceptional quality control.

4. Best Practices for Maintaining Sieving Equipment in Saffron Production

Regular maintenance of sieving machines is essential for long-term performance, food safety, and consistent saffron purity. Since saffron is highly valuable, machine efficiency and cleanliness must be a top priority.

Essential Maintenance Tips for Saffron Sieving Machines:

- Daily Cleaning Protocols:

- After each production batch, clean the sieve mesh and vibrating screens to remove any residual saffron particles.

- Use compressed air or a soft brush to prevent fine saffron dust from clogging the mesh.

- Routine Mesh Inspections:

- Check for any mesh tears, blockages, or loosened screens, as damaged mesh can lead to inconsistent sieving.

- Replace worn-out mesh to maintain optimal screening precision.

- Lubrication of Moving Parts:

- Regularly lubricate motor components and vibrating parts to ensure smooth operation and prevent machine wear.

- Calibration & Vibration Adjustment:

- Periodically adjust the vibration intensity to match the saffron’s sensitivity, ensuring gentle sieving without strand breakage.

- Preventing Cross-Contamination:

- When switching between different saffron batches, fully sanitize the sieving machine to prevent cross-contamination between grades.

Advantages of Proper Sieving Machine Maintenance:

✅ Ensures consistent saffron purity and quality

✅ Reduces machine downtime and production delays

✅ Increases the lifespan of the sieving equipment

✅ Prevents contamination risks, ensuring food safety compliance

By following best maintenance practices, Omani saffron producers can maximize equipment efficiency and sustain high production standards.

Final Thoughts

For Omani saffron producers looking to optimize processing and elevate purity standards, investing in the right sieving machines is a game-changer. By implementing impurity screening, selecting the best vibro sifting sieves, integrating sieving equipment into production lines, and maintaining machinery properly, saffron producers can enhance product quality, streamline operations, and increase profitability.

As global demand for premium-grade saffron rises, embracing advanced sieving technology will ensure that Omani saffron remains a top choice in the international market.