Introduction

In Oman’s flour industry, achieving superior product quality is essential to meet both local and international standards. A critical component in this pursuit is the implementation of advanced sieving machines, which play a pivotal role in refining flour texture, ensuring uniform particle size, and removing impurities. By integrating modern sieving technologies, Omani flour mills can enhance production efficiency, maintain consistency, and deliver products that cater to the evolving demands of consumers and regulatory bodies. This article explores the significance of advanced sieving machines in flour processing, highlighting key considerations for selection, recent technological advancements, and strategies for seamless integration into existing production lines.

Enhancing product quality in Oman’s flour industry necessitates a comprehensive understanding of advanced sieving technologies. Incorporating commercial sieve machines and fine screening techniques can significantly improve product consistency and operational efficiency. Below is an in-depth exploration of key aspects related to this topic:

1. The Critical Role of Commercial Sieve Machines in Flour Quality Enhancement

Commercial sieve machines are indispensable in the flour production process, primarily tasked with ensuring uniform particle size distribution and eliminating impurities. Achieving consistent particle sizes is vital, as it directly influences the physical properties of the final flour products, including texture, appearance, and performance. By effectively removing oversized particles and contaminants, sieve machines contribute to producing high-quality flour that meets stringent industry standards. For instance, plansifters are essential components in flour milling, efficiently separating particles and eliminating impurities to enhance flour quality, consistency, and uniformity. Miller Magazine+2LinkedIn+2Agriculture Institute+2

2. Key Features to Consider When Selecting a Commercial Sieve Machine for Flour Processing

Selecting the appropriate sieve machine requires careful consideration of several critical factors:

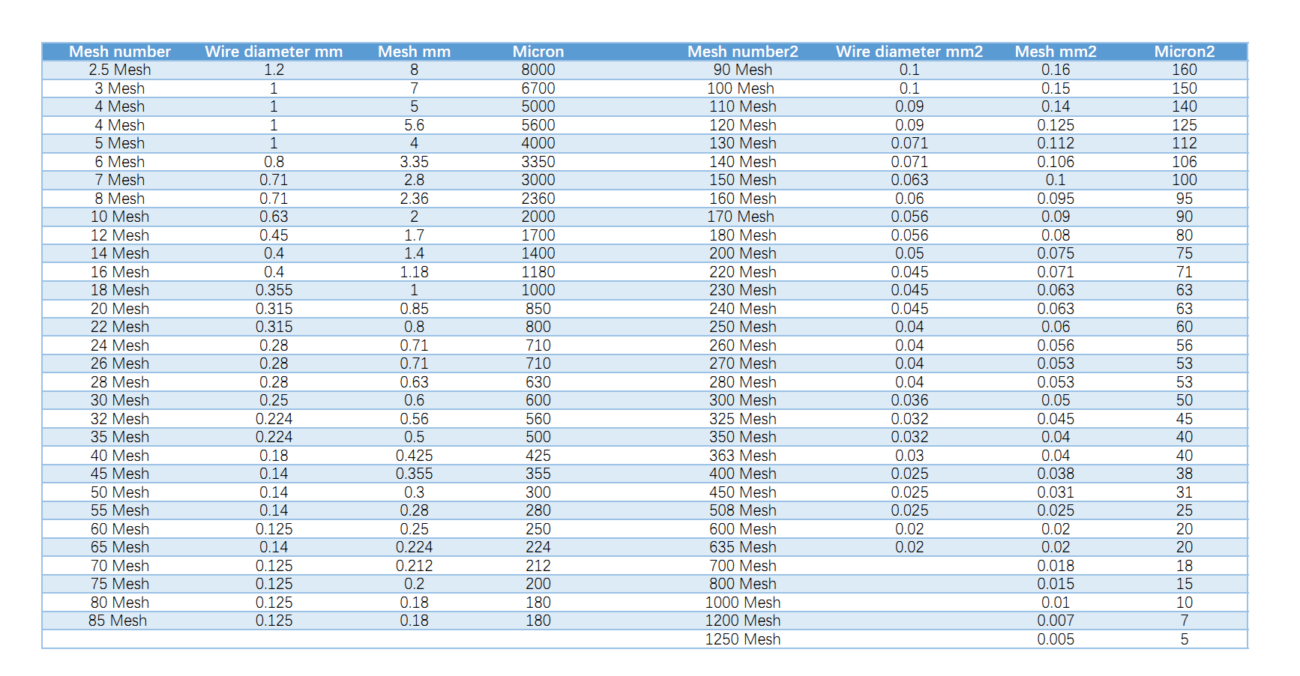

- Mesh Size and Accuracy: The machine should accommodate specific mesh sizes necessary for the desired particle size distribution, ensuring precise and efficient screening.

- Capacity and Throughput: It must align with production volume requirements, offering the necessary capacity to handle the expected throughput without compromising performance.

- Material Compatibility: Constructed from materials compatible with flour to prevent contamination and ensure durability.Gerber Instruments+9MicroMill+9The Official Alibaba.com Info Site+9

- Ease of Cleaning and Maintenance: Design features that facilitate straightforward cleaning and maintenance are essential to minimize downtime and maintain operational efficiency.

- Compliance with Food Safety Standards: Ensuring that the sieve machine meets industry regulations and standards is crucial for maintaining product quality and safety.

3. Advancements in Fine Screening Technology for the Flour Industry

The field of fine screening technology has witnessed significant advancements aimed at improving the efficiency and precision of flour manufacturing:

- Vibratory Screening Machines: These machines offer high-capacity safety screening of flour, removing contamination and improving product quality without compromising performance. Russell Finex

- Centrifugal Screens: Utilizing centrifugal force, these screens efficiently separate fine particles, enhancing the quality and consistency of flour products.

- Automated Sieving Systems: Modern sifters are equipped with sensors and AI-driven controls that optimize sifting speed, detect impurities, and adjust settings in real-time, minimizing human intervention and improving accuracy. Better English Study

4. Integrating Fine Screening Processes into Existing Flour Production Lines

Seamlessly incorporating fine screening processes into current production lines necessitates strategic planning:

- Process Flow Analysis: Evaluate the existing production workflow to identify optimal points for integrating sieving equipment without disrupting operations.

- Customization and Scalability: Select sieving machines that can be tailored to specific production needs and have the scalability to accommodate future growth.

- Automation and Control Systems: Implement machines equipped with advanced control systems to enable automation, real-time monitoring, and adjustments, enhancing overall efficiency.

- Training and Maintenance: Provide comprehensive training for operators and establish routine maintenance schedules to ensure the longevity and optimal performance of the sieving equipment.

Conclusion

The adoption of advanced sieving machines represents a strategic investment for Oman’s flour industry, directly impacting product quality and operational efficiency. By carefully selecting machines with appropriate features, staying abreast of technological advancements, and thoughtfully integrating these systems into current production processes, flour manufacturers can achieve consistent particle size distribution, enhance product purity, and meet stringent quality standards. Embracing these innovations not only strengthens the competitive position of Omani flour mills but also ensures the delivery of high-quality products that satisfy both domestic and international market expectations.