A Paradigm Shift in Almond Processing: The Technological Imperative

The global almond industry is experiencing a pivotal transformation, catalyzed by intensifying market demands for purity, uniformity, and operational efficiency. Traditional methods—once sufficient for small-scale production—are now largely obsolete in the face of exponentially growing consumption and evolving regulatory frameworks. As the need for precision and scalability intensifies, industrial processors are compelled to adopt intelligent, automated solutions. At the vanguard of this transformation stands Aman, a manufacturer whose machinery is not merely responding to industry trends but actively redefining them.

For decades, almond processors have contended with challenges ranging from inconsistent grading to high kernel damage rates during shelling. These inefficiencies compromise product quality and profitability. The pressing need for a mechanized approach that preserves the structural integrity of almonds while accelerating throughput has become indisputable. Aman‘s machinery addresses this necessity through integrated systems that harmonize shelling, cleaning, grading, and packaging in a seamless, closed-loop configuration. Such systems are no longer luxuries—they are operational necessities in a market where margins hinge on speed, safety, and consistency.

The backbone of this innovation lies in an architecture that prioritizes modular scalability and intelligent automation. Advanced programmable logic controllers (PLCs), high-resolution optical sorters, and food-grade materials define Aman‘s design ethos. Each machine is built to function autonomously yet cohesively within larger industrial ecosystems. This holistic engineering approach enables rapid deployment, minimal learning curves for operators, and robust adaptability to diverse almond varieties and regional harvesting methods. As a result, leading producers across North America, Europe, and the Asia-Pacific region have standardized their operations around Aman’s technology, confident in its ability to meet evolving consumer and regulatory expectations.

The Central Role of the Commercial Sieve Machine in Almond Optimization

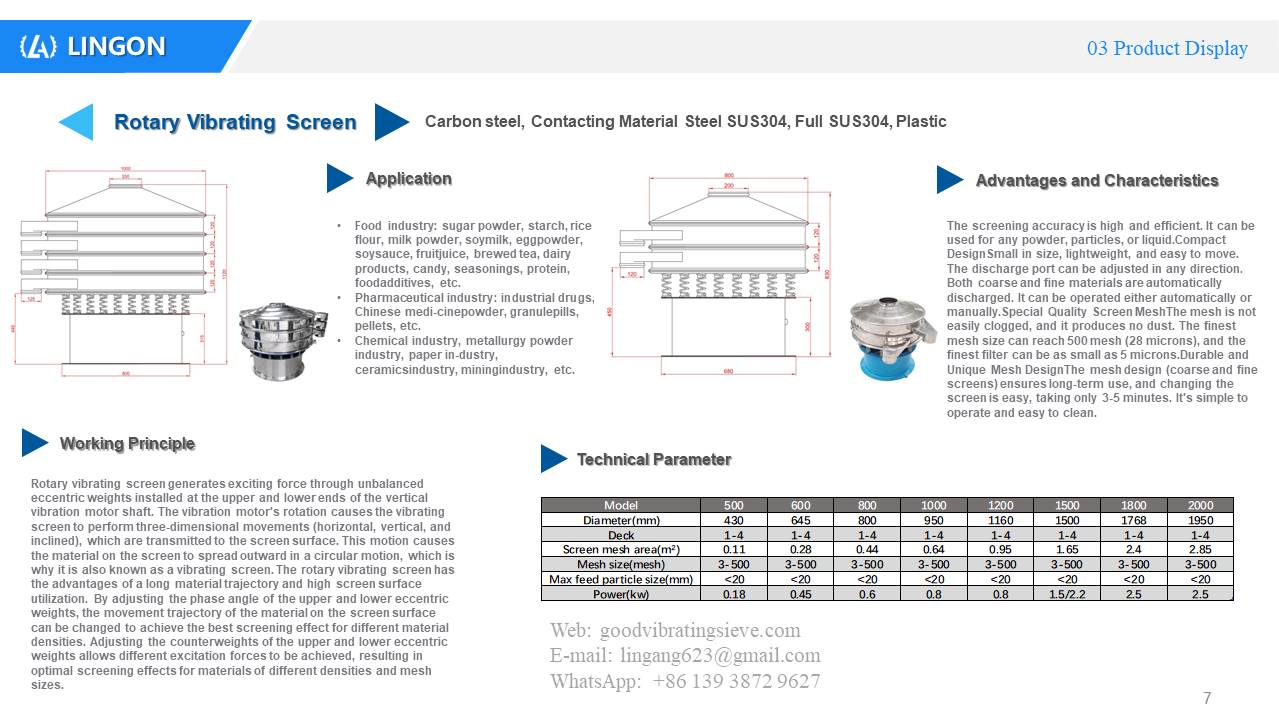

At the heart of modern almond processing lies the critical phase of particle classification—an area where minute inefficiencies can lead to significant losses. The implementation of the commercial sieve machine by Aman has decisively addressed this issue. Engineered to execute high-precision separation at industrial scales, this machinery represents a pinnacle in post-shelling and pre-packaging refinement. It ensures that kernels, fragments, hull residues, and foreign matter are sorted with scientific accuracy, safeguarding product purity and optimizing the commercial value of each output stream.

The commercial sieve machine is configured to utilize multi-tiered mesh systems with adaptive vibration controls. These mechanisms allow the machine to dynamically adjust to variable particle loads, maintaining consistent separation fidelity regardless of material input. What distinguishes Aman‘s design is not merely its throughput, but its capacity to maintain granular separation across a spectrum of almond sizes and densities without compromising kernel integrity. Such precision is vital in high-grade almond production, where even minor deviations can affect quality ratings and export eligibility.

Equipped with smart sensors and automated feedback loops, the machine conducts real-time monitoring of processing conditions. Data from vibration levels, sieve blockage, and particle flow rate are continuously analyzed, allowing instantaneous corrections without human intervention. These features substantially reduce the risk of equipment failure and production downtime. In addition, the hygienic design principles embedded into the machine—such as stainless-steel construction, smooth interior welds, and tool-free disassembly—ensure compliance with food safety standards including FDA, EFSA, and HACCP protocols.

Furthermore, the commercial sieve machine is seamlessly interoperable with other units in Aman‘s processing lines, such as shelling units, optical sorters, and packaging modules. This interoperability not only simplifies system integration but also enhances energy efficiency by synchronizing motor loads and reducing redundant mechanical operations. Producers utilizing this system report quantifiable improvements in kernel recovery rates, reduced material waste, and significant labor cost reductions—all critical metrics in large-scale almond processing.

Why Global Almond Producers Standardize with Aman’s Solutions

Almond cultivation spans geographies as diverse as California’s Central Valley, Spain’s Andalusian plains, and Australia’s Riverina region. Yet, across these varied agronomic landscapes, a common denominator has emerged: the industrial preference for Aman’s machinery. This widespread trust is not incidental; it is a direct consequence of the company’s relentless focus on technical refinement, durability, and operator-centric design. From boutique organic processors to multinational agri-corporations, stakeholders prioritize consistency, regulatory adherence, and output maximization—needs that Aman systematically fulfills.

One of the most compelling advantages of Aman’s machinery is its configurability. Unlike generic processing systems that offer limited customization, Aman provides machinery with interchangeable modules and adjustable settings tailored to unique processing environments. Whether the almonds are soft-shelled or hard-shelled, dry-farmed or irrigated, whole or blanched, the machinery adapts to optimize performance. This versatility significantly reduces the need for auxiliary equipment, shortens processing time, and allows operators to swiftly respond to crop variability or market-driven size preferences.

Another factor reinforcing Aman‘s industry leadership is its commitment to predictive maintenance and digital support ecosystems. Machines are embedded with telemetry systems capable of transmitting operational data to cloud-based dashboards. These dashboards not only alert managers to emerging mechanical issues but also provide performance analytics that inform batch planning, machine calibration, and staff deployment. The result is a smarter, leaner operation that minimizes waste and maximizes product consistency.

Aman also understands that machinery is only as effective as the people operating it. Thus, the company invests significantly in global training initiatives, offering comprehensive operator certification programs and multilingual technical support. These services, paired with user-friendly interfaces and extensive documentation, ensure that clients can fully harness the potential of the equipment without extended onboarding periods.

The impact of these combined strengths is measurable. Almond processors employing Aman‘s systems consistently report higher yields, faster throughput, and superior grading consistency compared to legacy systems. Moreover, processors exporting to high-regulation markets—including Japan, Germany, and the United Arab Emirates—value Aman’s machinery for its traceability features and contaminant control mechanisms. These capabilities facilitate seamless compliance with export requirements, thereby reducing shipment rejections and elevating brand credibility in competitive global markets.

In conclusion, the almond processing sector has entered an era where technology defines competitive advantage. Amidst this landscape, Aman stands as a technological and strategic partner of choice for top-tier producers. Its integration of automation, machine intelligence, and precision-engineered systems—anchored by the performance of the commercial sieve machine—redefines what is possible in industrial almond processing. As the industry continues to globalize and quality benchmarks rise, the decision to standardize with Aman is not just a matter of operational efficiency. It is a definitive step toward enduring relevance, resilience, and profitability.