Introduction

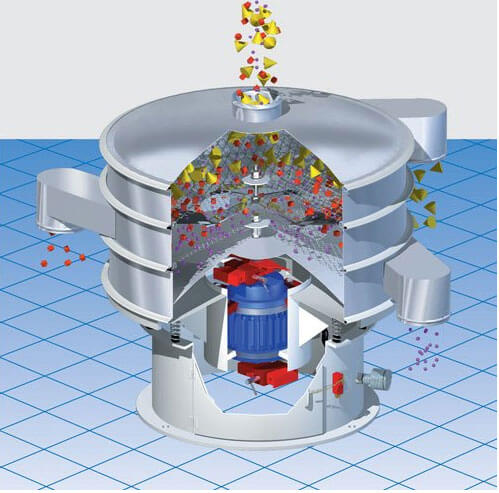

The powder coatings and paints industry is one of the fastest-growing segments in the global manufacturing sector, driven by demand for durable, eco-friendly, and aesthetically appealing finishes. Consistency in particle size and purity is crucial for achieving smooth coatings, vibrant colors, and long-lasting performance. Vibrating screens play a vital role in the production of powder coatings and pigments by ensuring precise classification, removing impurities, and maintaining product uniformity. This article explores how vibrating screens contribute to quality, efficiency, and sustainability in powder coatings and paints manufacturing.

Importance of Particle Size in Powder Coatings and Paints

- Surface Finish Quality – Uniform particle sizes lead to smooth, defect-free coatings.

- Color Consistency – Consistent pigment distribution ensures accurate color matching across batches.

- Application Efficiency – Properly sized powders improve electrostatic spray efficiency in powder coating.

- Durability – Eliminating oversized or undersized particles enhances coating adhesion and longevity.

- Regulatory Compliance – Meeting strict standards for particle size distribution and purity is essential in coatings production.

Applications of Vibrating Screens in Coatings and Paints

Powder Coating Production

Vibrating screens classify powders into desired fractions, removing oversized particles and fines to ensure uniform feedstock for application.

Pigment Screening

Pigments used in paints and coatings are screened to eliminate impurities and achieve consistent particle size for accurate coloration.

Resin Powder Screening

Resins, a core component of powder coatings, are screened to achieve the required granule size for smooth application.

Recycled Powder Reclamation

In powder coating systems, unused overspray powder is often reclaimed. Vibrating screens filter out contaminants before reintroducing the powder into the system.

Additive Processing

Specialty additives like flow agents, curing agents, and stabilizers are screened to ensure proper dispersion and performance.

Benefits of Vibrating Screens in Powder Coatings and Paints

- Enhanced Product Quality – Consistent particle size improves coating smoothness and color accuracy.

- Reduced Waste – Oversized or undersized material is reprocessed, minimizing losses.

- Improved Production Efficiency – High-capacity vibrating screens process large batches quickly.

- Better Spray Performance – Uniform powders enhance electrostatic coating efficiency.

- Worker Safety – Enclosed screening systems reduce exposure to fine powder dust.

- Cost Savings – Reduced material waste and higher product quality improve profitability.

Key Features for Vibrating Screens in Coatings Applications

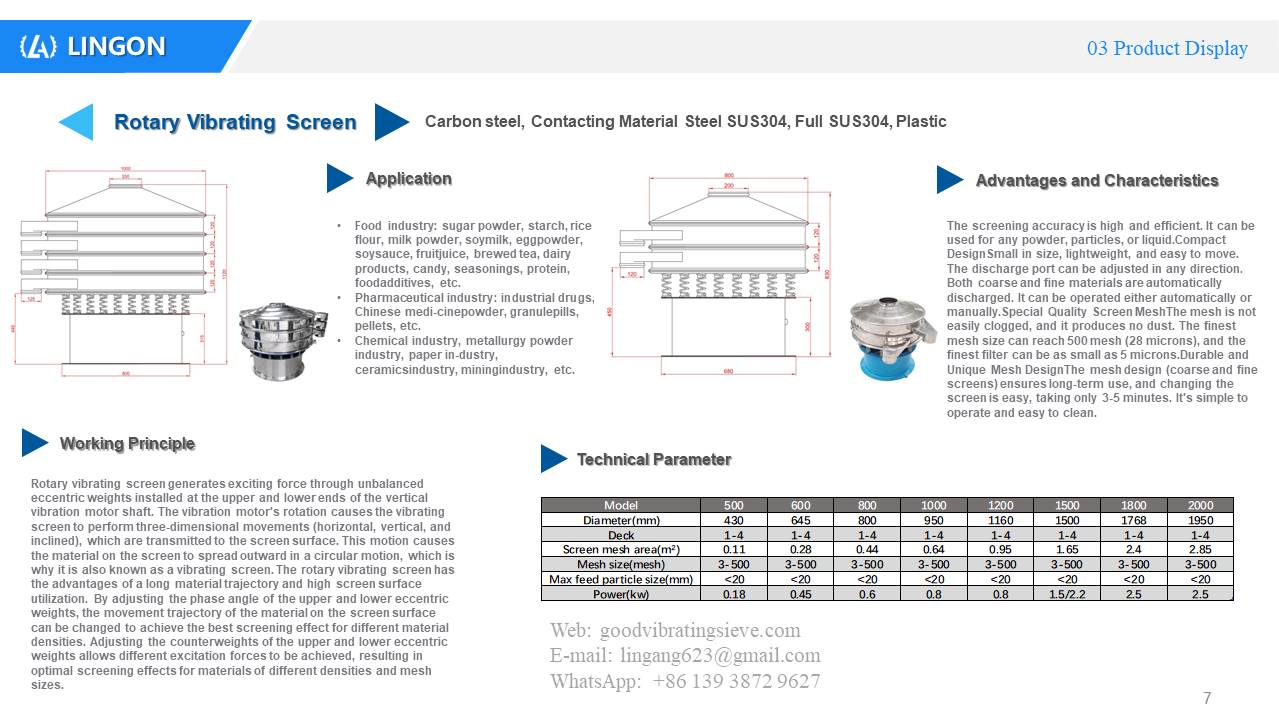

- Fine Mesh Capability: Screens capable of handling ultra-fine powders (down to microns).

- Anti-Blinding Technology: Ultrasonic cleaning systems prevent mesh clogging when screening fine or sticky powders.

- Dust Control Systems: Enclosures and extraction units minimize airborne dust hazards.

- Stainless Steel Construction: Prevents contamination and ensures durability.

- Multi-Deck Design: Enables separation into multiple size fractions.

Technological Innovations

- Ultrasonic Vibrating Screens – Essential for fine powder classification, preventing clogging and ensuring accuracy.

- Smart Sensors – IoT-enabled systems monitor screen performance, predict maintenance, and ensure consistent output.

- Energy-Efficient Motors – Reduce operational costs while maintaining high screening efficiency.

- Integrated Production Lines – Vibrating screens connect seamlessly with mixers, extruders, and milling equipment.

Case Study: Powder Coating Plant in North America

A large powder coatings manufacturer integrated ultrasonic vibrating screens into its production line. The system classified resin powders and pigments into precise fractions, reducing particle size variation. As a result, the company achieved a 25% improvement in coating smoothness, reduced overspray waste, and improved customer satisfaction with consistent colors and finishes.

Future Outlook: Vibrating Screens in Advanced Coatings

The future of powder coatings and paints will increasingly depend on advanced screening technologies to:

- Enable ultra-fine classification for high-performance coatings.

- Support eco-friendly formulations with minimal waste.

- Improve reclaim systems for circular economy practices.

- Integrate with smart manufacturing systems for real-time quality control.

Conclusion

In the competitive powder coatings and paints industry, quality and consistency are non-negotiable. Vibrating screens are at the core of achieving these standards, ensuring accurate particle size distribution, impurity removal, and efficient production. From pigment preparation to powder coating reclamation, vibrating screens deliver measurable improvements in product performance, cost efficiency, and sustainability. For manufacturers aiming to meet growing global demand and stricter environmental standards, advanced vibrating screen technology is an investment in both quality and long-term success.