Introduction

Refractory materials are the backbone of industries that operate at extremely high temperatures, such as steelmaking, glass production, cement, and petrochemicals. These materials—including alumina, silica, magnesia, and zircon—must withstand intense heat, mechanical stress, and chemical corrosion. Achieving consistent particle size and purity during refractory production is essential to ensure durability and performance. Vibrating screens play a critical role in this process by classifying, de-dusting, and refining raw and processed refractory materials. This article explores the applications, benefits, and technological innovations of vibrating screens in the refractory industry.

The Role of Refractories in Industry

- Steel Industry – Linings for blast furnaces, ladles, and converters.

- Glass Production – Furnaces and kilns require refractory bricks and castables.

- Cement Plants – Kiln linings and preheaters depend on high-grade refractory materials.

- Petrochemicals – Reactors and thermal cracking units rely on refractory protection.

For each of these applications, the performance of refractory materials depends heavily on uniformity, purity, and particle size distribution—areas where vibrating screens deliver measurable value.

Applications of Vibrating Screens in Refractory Processing

Raw Material Preparation

Refractory production begins with raw minerals such as alumina, silica, or magnesia. Vibrating screens classify these raw materials into precise size ranges before mixing or shaping.

Crushing and Grinding Oversight

After crushing, vibrating screens separate fine powders from oversized particles, ensuring consistent feed for milling and shaping processes.

Screening of Castables and Mortars

Specialized refractory mixes require uniform particle sizes to achieve proper setting, bonding, and high-temperature resistance.

Recycling of Used Refractories

Spent refractories from furnaces are recycled to recover valuable minerals. Vibrating screens separate reusable particles from dust, slag, and contaminants.

Quality Control in Final Products

Powders and granules used in bricks, castables, and monolithic refractories are screened to ensure product uniformity before forming and firing.

Benefits of Vibrating Screens in Refractory Materials

- Improved Material Uniformity – Ensures consistent quality for high-performance refractories.

- Reduced Impurities – Removes dust, slag, and foreign matter for cleaner raw materials.

- Operational Efficiency – Accelerates large-scale processing with high throughput.

- Enhanced Product Performance – Uniform particle sizes lead to stronger, more durable refractories.

- Waste Reduction – Reprocessing oversize and fine materials minimizes losses.

- Worker Safety – Enclosed screening systems reduce dust exposure in production facilities.

Key Features for Refractory Vibrating Screens

- High-Strength Construction: Designed to handle abrasive and dense materials.

- Multi-Deck Designs: Enable multiple fractions for different refractory products.

- Fine Mesh Options: Provide precise classification for powders and fine aggregates.

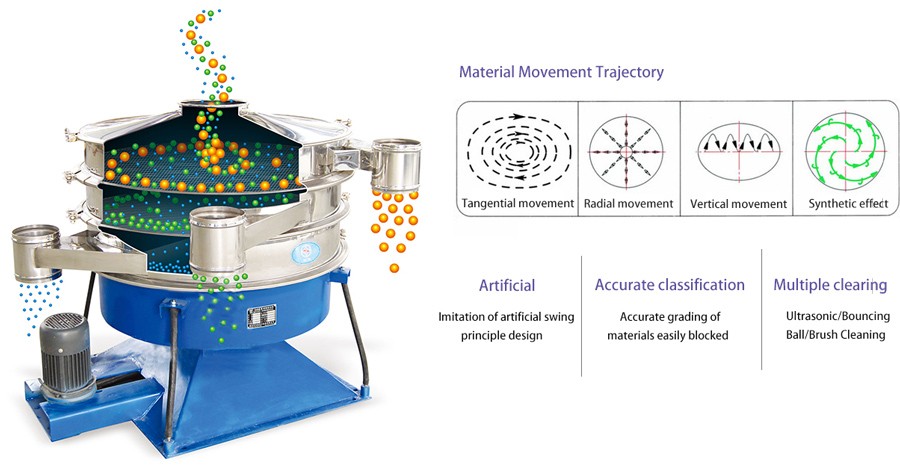

- Anti-Blinding Systems: Essential for sticky or moist refractory raw materials.

- Dust Control Mechanisms: Minimize airborne particulates in processing plants.

Technological Innovations

- Ultrasonic Vibrating Screens – Ensure accurate screening of ultra-fine refractory powders.

- IoT Integration – Smart sensors monitor screen performance, enabling predictive maintenance.

- Hybrid Power Solutions – Useful for remote refractory mining and processing sites.

- Energy-Efficient Designs – Lower power consumption without compromising throughput.

Case Study: Refractory Plant in Europe

A European refractory manufacturer producing alumina-silicate bricks integrated multi-deck vibrating screens into its production line. The screens efficiently classified crushed raw material into uniform size fractions, reduced impurities, and ensured precise feedstock for shaping and firing. As a result, the company achieved improved product consistency, reduced kiln defects, and a 12% increase in production efficiency.

Future Outlook: Vibrating Screens in High-Temperature Industries

As industries demand more durable and high-performance refractories, vibrating screens will continue to play a key role in:

- Supporting the production of advanced monolithic and eco-friendly refractories.

- Enabling recycling of spent refractories for sustainable material use.

- Integrating with fully automated processing lines for Industry 4.0 compliance.

- Enhancing global supply chain reliability with consistent quality assurance.

Conclusion

The refractory industry demands precision, durability, and consistency to meet the needs of high-temperature applications across steel, glass, cement, and petrochemicals. Vibrating screens are essential to achieving these standards, offering efficient classification, impurity removal, and uniformity in raw and processed materials. For refractory manufacturers, investing in advanced vibrating screen technology translates into higher product quality, improved efficiency, and long-term competitiveness in a global market.