1. Introduction: Efficiency Is the Key to Modern Legume Processing

Peanuts and soybeans are among the world’s most important legumes, widely used for food products, edible oils, animal feed, and industrial ingredients. As global demand for high-quality, contaminant-free legumes continues to increase, processing facilities face mounting pressure to enhance product quality, reduce waste, and improve operational efficiency.

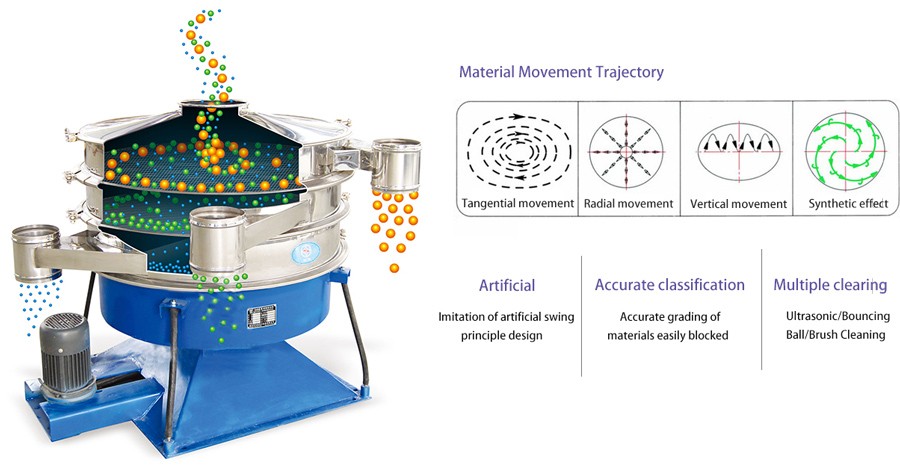

One of the most critical — yet often underestimated — components in the processing line is vibrating screening technology. By integrating modern vibrating screens into peanut and soybean processing plants, manufacturers can significantly improve impurity removal, size classification, drying efficiency, and overall throughput.

From pre-cleaning raw harvests to preparing final products for packaging, precision screening ensures consistent product quality and stable production.

2. Processing Challenges in Peanut & Soybean Production

Despite advances in processing technologies, peanut and soybean processors face persistent operational difficulties:

- 🌾 Foreign Contaminants: Harvested peanuts and soybeans often contain stones, twigs, husks, and dust that must be removed to meet food safety standards.

- 🫘 Size Variation: Raw materials often include broken kernels, undersized seeds, and oversized foreign matter, which require effective grading.

- 💨 Moisture & Stickiness: Especially in humid regions, moisture can cause clogging and blinding of traditional sieves.

- ⚙️ High Throughput Requirements: Large processing plants must handle huge volumes without compromising separation accuracy.

- 📈 Yield Optimization: Broken or misclassified beans lead to reduced sellable yield and lower profitability.

Traditional static screens or rotary sifters often cannot keep up with modern capacity demands. Vibrating screens solve these challenges through high-speed separation, adaptable mesh sizes, and self-cleaning capabilities.

3. The Role of Vibrating Screens in Legume Processing

a. Pre-Cleaning and Impurity Removal

The first step in peanut and soybean processing involves removing foreign materials like stones, shells, straw, and soil clumps. Circular or linear vibrating screens are ideal for this stage because they can process large volumes quickly while accurately separating oversized or undersized particles.

b. Grading and Size Classification

Vibrating screens can classify kernels by size — separating whole nuts, broken pieces, and fines. Multi-deck screens enable processors to achieve multiple grades in a single pass, improving downstream processing efficiency.

c. Dehydration and Dust Removal

After washing or blanching, peanuts and soybeans need to be dried efficiently. Vibrating screens with perforated decks or mesh can help remove excess water and filter out fine particles and dust, ensuring cleaner products and preventing contamination.

d. Pre-Packaging Inspection

In the final stage, high-precision screens act as quality control checkpoints. They ensure uniform product size and eliminate any remaining contaminants, boosting consumer confidence and compliance with export standards.

4. Key Advantages of Vibrating Screens in Peanut & Soybean Processing

| Feature | Benefit to Processing Line |

|---|---|

| High screening accuracy | Precise grading of whole kernels vs. broken or undersized ones |

| High capacity | Handles bulk volumes with minimal loss of efficiency |

| Self-cleaning systems | Reduces screen blinding from moisture or oil residues |

| Gentle handling | Minimizes kernel breakage compared to mechanical sifters |

| Modular design | Adapts to various processing stages easily |

| Stainless steel construction | Meets food hygiene standards and resists corrosion |

| Easy maintenance | Quick mesh change and cleaning reduce downtime |

These advantages make vibrating screens a cost-effective, scalable solution for modern peanut and soybean processing plants.

5. Typical Applications Along the Processing Line

| Processing Stage | Screening Objective | Recommended Screen Type |

|---|---|---|

| Raw Material Pre-cleaning | Remove stones, sticks, husks, soil | Circular vibrating screen |

| Shelling / Cracking Stage | Separate broken shells and kernels | Linear vibrating screen |

| Size Grading | Classify kernels by size and quality | Multi-deck linear screen |

| Drying & Dust Removal | Eliminate excess moisture and fines | Perforated deck screen |

| Final Inspection | Quality control before packaging | High-precision screening unit |

This multi-stage integration ensures higher yields, lower contamination, and uniform product quality throughout the processing flow.

6. Technological Innovations in Vibrating Screens for Legumes

Modern vibrating screens for peanut and soybean processing incorporate advanced features that go beyond basic separation:

- Ultrasonic Deblinding Systems: Prevent clogging during fine powder or bran screening.

- Frequency Control: Adjust vibration intensity for different bean varieties or processing stages.

- Integrated Dust Collection: Minimize airborne particles and improve hygiene.

- Hygienic Design: Rounded corners, smooth surfaces, and stainless steel construction for easy cleaning.

- Automation & Monitoring: Real-time performance data allows processors to fine-tune operations and predict maintenance needs.

These features make vibrating screens indispensable for modern, high-capacity peanut and soybean processing lines.

7. Case Example: Upgrading a Peanut Processing Facility

A peanut processor in West Africa modernized its pre-cleaning and grading line by installing two linear vibrating screens with multi-deck configurations. Within six months, the facility achieved:

- 📈 15% increase in overall yield, due to better size grading and reduced losses

- 🧼 98% removal of foreign contaminants during pre-cleaning

- ⏱ 30% shorter processing time compared to rotary sifters

- ⚡ Lower energy consumption thanks to optimized motor efficiency

This investment not only improved output quality but also boosted profitability through better market value and export compliance.

8. Future Trends: Smart Screening and Sustainability

The peanut and soybean industries are increasingly turning toward smart, automated screening solutions to keep up with global demand. Key trends include:

- IoT-enabled sensors for monitoring screen performance in real time

- Predictive maintenance to minimize unplanned downtime

- Energy-efficient drives that reduce operational costs

- Integration with sorting and grading robots for fully automated lines

- Recycling and by-product utilization, where vibrating screens separate skins, fines, or powder for secondary use

Such innovations are paving the way for next-generation processing plants that are efficient, sustainable, and globally competitive.

9. Conclusion

Vibrating screens are more than just auxiliary equipment — they are core components in modern peanut and soybean processing lines. By delivering precise grading, high throughput, effective impurity removal, and low maintenance, they help processors meet stringent quality standards while maximizing yield and profitability.

For producers aiming to stay ahead in the competitive agricultural processing industry, investing in advanced vibrating screening technology is both a strategic and operational advantage.