In the high-demand world of sesame seed processing, achieving exceptional product purity and uniformity is not optional—it’s essential. Global markets require sesame seeds that are impeccably clean, uniformly sized, and free from contaminants, a standard that traditional methods often struggle to meet. Recognizing this challenge, Aman, a renowned manufacturer in the agro-processing industry, has developed a state-of-the-art sesame seeds vibrating screen machine designed to streamline sorting, grading, and impurity removal with surgical precision. This machine redefines industrial screening by delivering consistent, export-grade results with maximum efficiency and minimal product loss.

Engineering Precision for a Global Commodity

Sesame seeds, though diminutive in size, command significant importance in global trade due to their culinary, nutritional, and cosmetic applications. Their small scale and high sensitivity to contamination make the separation and grading process both technically demanding and commercially critical. In export-focused operations, even minimal impurities can result in batch rejection, creating substantial financial losses. Amid this high-stakes environment, Aman has emerged as a pioneering force, offering precision-engineered machinery that has set a new benchmark in sesame seed separation.

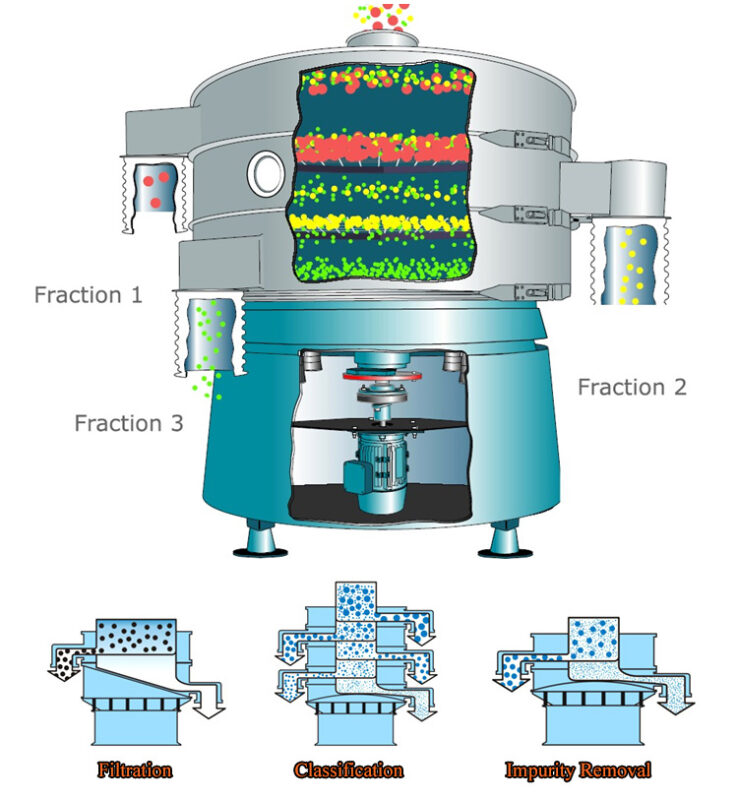

At the core of Aman’s technological superiority lies a design philosophy that prioritizes both mechanical integrity and operational finesse. The vibrating screen system is developed with acute attention to amplitude modulation, mesh aperture alignment, and anti-blinding mechanisms—all tailored to accommodate the fragility and lightweight nature of sesame seeds. The structure integrates a multi-deck design where each layer filters specific particle sizes, ensuring uniformity in final output. This granularity in design reflects an understanding of not just engineering principles but also the agronomic variability inherent in sesame seed batches sourced from different geographies.

Moreover, the screen system is especially suitable for fine screening during export, where stringent quality parameters must be adhered to. These include the removal of minute impurities such as sand particles, immature seeds, and foreign seed varieties. Aman’s equipment ensures this degree of selectivity without compromising on processing speed, a balancing act that many conventional machines fail to maintain. By using finely tuned vibratory motors calibrated for high-frequency oscillation and consistent energy distribution, the system guarantees homogeneity in output and maximizes seed integrity throughout the grading process.

Complementing the primary separation mechanism is an integrated feed control unit, which ensures that incoming seed flow remains constant, thereby preventing overloading and ensuring each grain receives optimal exposure to the screening surface. This attention to controlled throughput is a defining feature of high-end industrial separators and reinforces Aman’s position as a manufacturer of distinction. As global markets continue to demand ever-higher levels of purity, consistency, and processing traceability, such innovations are not just beneficial—they are indispensable.

Post-Harvest Perfection: Grading, Sifting, and Contaminant Removal

Post-harvest sesame seed processing is an intricate task that demands systematic interventions to refine raw material into an export-ready product. Among the most critical phases is the stage that occurs after shelling, when the seed is highly susceptible to fragmentation, dust adherence, and admixture with residual husk particles. It is at this juncture that the true value of an advanced vibrating screen system becomes evident. Designed to grade and sieve out impurities with micrometric precision, Aman’s machinery delivers a uniform, contaminant-free product ideal for high-stakes markets in Europe, North America, and the Middle East.

The separation process begins with an automated feed hopper that ensures an even and measured flow onto the primary sieve deck. The system’s multi-level vibratory architecture uses differential mesh sizes to progressively stratify material according to particle size and density. This cascading arrangement allows for simultaneous classification and decontamination—an engineering triumph rarely achieved in traditional screening solutions.

Notably, the machinery incorporates a dual-action vibratory mechanism: vertical agitation for de-clumping and horizontal motion for linear separation. This hybrid motion ensures that even the most stubborn contaminants—such as fibrous husk remnants and insect fragments—are efficiently expelled. Each pass through the screen refines the seed lot, and through multiple iterations, the product attains international-grade uniformity and purity.

The sieve shaker machine plays a pivotal role in this refinement. Unlike conventional static sieves that rely on gravity alone, the sieve shaker machine applies controlled vibrational energy to dislodge, stratify, and channel particles through precisely engineered apertures. With adjustable vibration frequencies, it allows operators to adapt to different seed moisture levels and impurity loads, thereby ensuring optimal efficiency regardless of batch variability. Its robust construction, coupled with low noise operation and minimal maintenance requirements, positions it as an essential asset for any sesame seed processing facility with high-volume throughput needs.

Supporting this advanced screening infrastructure is Aman’s integration of real-time monitoring and diagnostics. Sensor-equipped nodes track factors such as sieve load, vibration symmetry, and motor temperature, allowing for predictive maintenance and minimizing unexpected downtime. This digital augmentation not only improves productivity but also ensures compliance with increasingly rigorous traceability and documentation norms demanded by export regulations. For producers looking to meet the gold standard in sesame seed processing, Aman delivers not just a machine, but a fully optimized, high-performance ecosystem.

Industrial Reliability Meets Export-Grade Consistency

In a sector defined by fine tolerances and unforgiving quality control regimes, processing reliability is paramount. Producers must deliver products that meet stringent phytosanitary and compositional standards, batch after batch. Failure to comply can mean not just lost shipments, but compromised trade relationships and reputational damage. Recognizing this, Aman has engineered its sesame seed vibrating screen system with a focus on industrial-grade dependability, continuous operation, and minimal human intervention.

The heart of the system is the commercial sieve machine, a precision instrument that operates under prolonged stress conditions without faltering. Built from corrosion-resistant alloys and using food-grade contact materials, it resists both mechanical wear and microbial colonization. Its modular design facilitates rapid screen changes and cleaning, enabling processors to switch between seed varieties or sizes without extensive downtime. This is critical for contract manufacturers handling diverse export orders on tight timelines.

Functionality is further enhanced through aerodynamic dust control enclosures that maintain hygienic processing zones while minimizing airborne particulate contamination. These enclosures work in tandem with vacuum-assisted waste ejection systems that transport debris to sealed collection units, ensuring cleanliness and safety throughout the processing area. The resultant working environment not only complies with international standards but also improves worker health and productivity.

What truly distinguishes Aman‘s equipment, however, is its adaptability. Whether deployed in a high-capacity export plant or a mid-sized regional facility, the machinery scales fluidly without compromise. Add-on modules such as magnetic separators, de-stoners, and moisture controllers can be seamlessly integrated, creating a custom-tailored processing line. This makes the system ideal for processors managing complex portfolios and needing flexibility without sacrificing precision.

The incorporation of Internet of Things (IoT) features represents the cutting edge of Aman’s technological roadmap. Operators can monitor machine status, production metrics, and service intervals from remote dashboards. Integration with Enterprise Resource Planning (ERP) systems allows real-time reporting of yield rates, impurity levels, and machine performance. These insights enable data-driven decisions that optimize production efficiency, reduce resource wastage, and improve profitability.

As the sesame seed industry continues to expand—driven by growing global demand and stringent consumer expectations—only the most resilient, intelligent, and precise equipment will sustain long-term success. Through a fusion of engineering excellence, operational efficiency, and technological foresight, Aman’s vibrating screen system stands as the definitive solution for processors seeking not just functionality, but industry leadership.

Aman’s commitment to redefining sesame seed processing through the strategic application of vibratory separation technology reflects an unyielding pursuit of excellence. From grading and sieving out impurities after shelling to executing fine screening during export with their precision-driven commercial sieve machine and high-performance sieve shaker machine, Aman has engineered a paradigm shift in seed purification. For stakeholders across the agricultural export value chain, the brand’s machinery represents more than operational equipment—it represents a commitment to quality, integrity, and innovation that elevates sesame seed processing to a global standard.