How Vibrating Screens Improve Ultra Fine Screening for Cassava Flour

When producing cassava flour, precision is crucial. Ultra-fine particles determine the texture and quality of the final product, especially for applications like gluten-free baking or processed foods. Vibrating screens excel at ultra-fine screening by utilizing high-frequency vibrations to separate particles with exceptional accuracy.

The key lies in their ability to maintain consistent movement of cassava particles across the mesh, ensuring smaller granules pass through while larger impurities are removed. This reduces the risk of clogging, which can delay production. By using the right vibrating screen, you can achieve a smooth, uniform texture in the flour without sacrificing production speed.

Moreover, vibrating screens equipped with ultrasonic technology take ultra-fine screening to the next level. These systems add high-frequency vibrations on top of the base motion, breaking up agglomerated particles and further enhancing separation. This is particularly valuable when processing wet or sticky cassava that could otherwise form lumps, compromising product quality.

In short, a vibrating screen ensures your cassava flour meets the highest standards of fineness and consistency, giving you an edge in the competitive food industry.

Maximizing Manufacturing Output with High-Performance Vibratory Separators

Manufacturing efficiency is the backbone of profitable cassava flour production. High-performance vibratory separators allow you to process large quantities of cassava quickly while maintaining the desired quality.

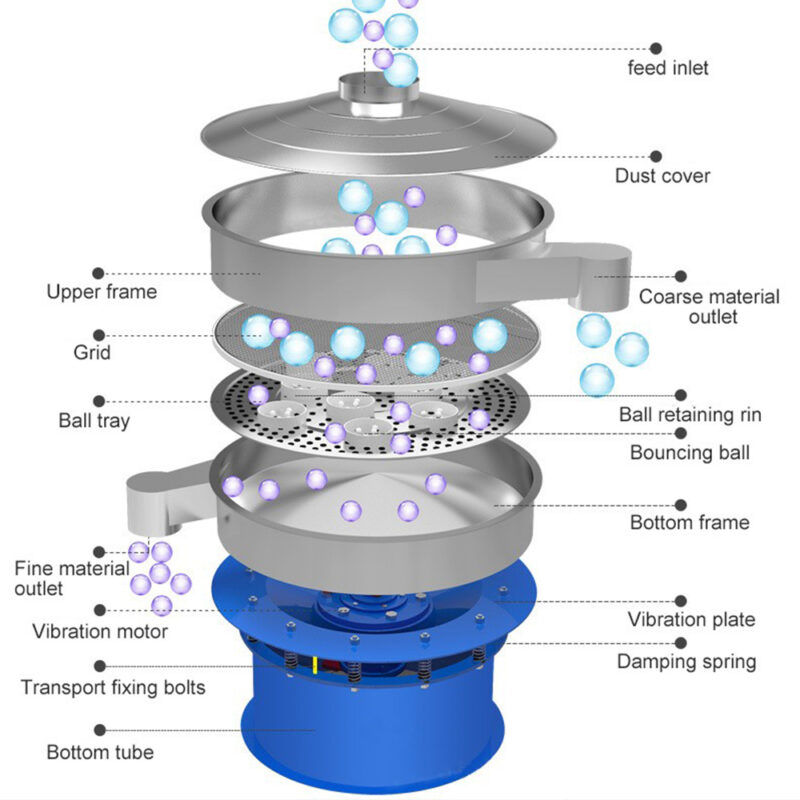

These machines are built for durability and speed, handling heavy loads without compromising performance. Features like adjustable amplitude and multi-deck configurations allow for simultaneous separation of various particle sizes, eliminating the need for additional equipment. For cassava flour, this means separating fine particles from fibers and other impurities in one seamless step.

Vibratory separators with optimized motor designs also reduce energy consumption, making them both cost-effective and environmentally friendly. Automation features such as self-cleaning screens and real-time monitoring systems further streamline the process, minimizing downtime and labor requirements.

A well-chosen vibratory separator can double or even triple manufacturing output, enabling producers to meet growing demand while maintaining consistent quality. For cassava flour production, this is a game-changer, turning labor-intensive processes into efficient, scalable operations.

Streamlining Cassava Flour Manufacturing with Modern Vibratory Technology

Integrating modern vibratory technology into cassava flour manufacturing simplifies the production process and improves overall operational efficiency. Advances in screen design, motor efficiency, and material handling systems have made vibrating screens more reliable and versatile than ever.

Modern vibrating screens feature modular designs, allowing manufacturers to customize the equipment for specific requirements. For instance, finer meshes can be used for premium-grade cassava flour, while coarser screens handle bulk processing. Machines with dual-motor setups offer more precise control over vibration intensity, catering to both delicate and heavy-duty operations.

Moreover, automated vibratory systems equipped with digital controls can monitor performance in real time, providing alerts for maintenance or blockages. This prevents costly disruptions and ensures uninterrupted production. Some systems even offer remote operation, enabling manufacturers to manage multiple machines from a centralized location.

By streamlining production with modern vibratory technology, cassava flour producers can minimize waste, reduce energy consumption, and ensure product consistency. The result? A more efficient, scalable, and profitable operation capable of meeting the diverse demands of the global market.