When it comes to material screening and separation, the performance of a shaker can make all the difference in optimizing industrial processes. Whether it’s used in mining, food production, or pharmaceuticals, a well-performing shaker is crucial for throughput, quality, and overall operational efficiency. But what determines a shaker’s performance, and how can you ensure it functions at its best? In this post, we’ll dive into the factors that impact shaker performance and tips to maximize its efficiency.

Understanding Shaker Performance

Shaker performance refers to how effectively the machine separates materials according to size and weight specifications. A high-performing shaker will consistently achieve the desired separation results while operating efficiently, with minimal downtime or maintenance issues. There are several critical elements that directly affect a shaker’s performance, ranging from its design and operation to the type of material being processed.

Key Factors Affecting Shaker Performance

- Vibration Intensity and Frequency The core of a shaker’s operation is its vibrational motion. The intensity and frequency of these vibrations dictate how efficiently materials are separated.

- Vibration Intensity: Higher intensity can move larger materials more effectively, while finer materials may require a lower intensity to avoid blinding the screen.

- Frequency: The vibration frequency should match the type of material being processed. Coarser materials usually need lower frequencies, while finer materials benefit from higher frequencies to facilitate better separation.

- Screen Mesh Size and Quality The size of the mesh openings is another critical factor in shaker performance. The mesh size determines the particle size distribution that passes through the screen.

- Smaller mesh sizes provide more precise separation but may lead to clogging if the material is too coarse.

- Larger mesh sizes allow for faster throughput but can compromise accuracy.

- Material Characteristics The type of material being processed can greatly influence how well the shaker performs. Key factors include:

- Moisture content: High moisture levels can cause materials to stick together, reducing the effectiveness of the screen and increasing the likelihood of clogging.

- Particle shape and size: Irregularly shaped particles may pass through screens differently than uniform particles, which may impact the efficiency of separation.

- Density: Denser materials may require different vibration settings or screen mesh sizes compared to lighter materials.

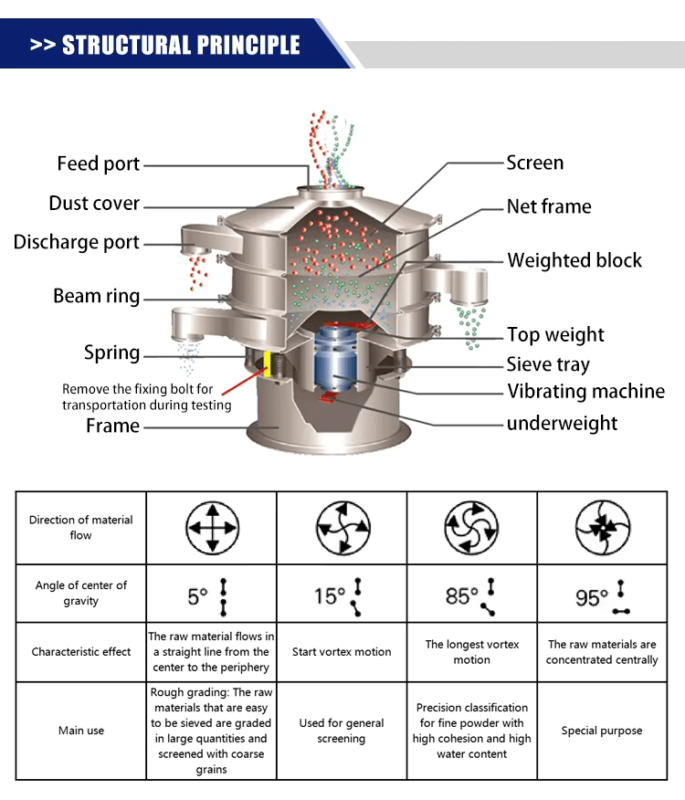

- Shaker Design and Setup The design of the shaker itself can influence its performance. Factors such as the number of screen decks, the angle of the shaker, and the material flow direction can affect screening efficiency.

- Multi-deck designs: These allow for more complex separation of different particle sizes, improving efficiency for processes requiring multiple gradations.

- Shaker inclination: A steep angle may increase material throughput but can reduce separation accuracy, while a shallower angle can enhance precision at the cost of speed.

- Proper Maintenance and Operation Regular maintenance is essential to ensuring a shaker performs optimally. Some of the most common issues that affect shaker performance—like screen clogging, motor malfunctions, or wear and tear—can be avoided with proper upkeep.

- Routine inspections: Regularly check for screen damage, motor issues, and any signs of wear on the vibratory components.

- Lubrication: Make sure bearings and other moving parts are lubricated to prevent unnecessary wear and overheating.

- Cleaning: Accumulated material on the screen or in the system can cause blockages and hinder performance. Cleaning the shaker frequently helps maintain optimal operation.

Tips for Maximizing Shaker Performance

- Optimize Vibration Settings: Tailor the shaker’s vibration frequency and intensity to the specific material you’re working with. Testing different settings can help you find the most efficient parameters for your operation.

- Select the Right Screen: Choose screen sizes and materials that are best suited for your specific application. Finer meshes are ideal for small particle separation, while coarser meshes work better for larger particles.

- Manage Material Feed Rate: Overloading the shaker can significantly reduce its performance. Ensure a consistent and appropriate feed rate to maintain efficiency and avoid clogging or material buildup on the screen.

- Monitor and Adjust Regularly: Continuous monitoring of the shaker’s performance can help detect issues early. Adjust settings based on real-time performance data to optimize separation efficiency and minimize downtime.

- Invest in High-Quality Components: A shaker is only as good as the components it’s built from. Using high-quality parts, especially screens and motors, can improve longevity and ensure consistent performance, even in high-demand applications.

Signs of Poor Shaker Performance

Recognizing when your shaker is underperforming can help you address problems before they escalate. Some common signs include:

- Inconsistent material separation: When the output doesn’t meet size specifications, it could indicate issues with vibration settings, screen wear, or material overload.

- Reduced throughput: If the shaker isn’t processing materials as quickly as expected, it may be a sign of screen clogging or improper feed rate.

- Excessive noise or vibration: Unusual sounds or shaking could point to motor or bearing issues, which require immediate attention.

Conclusion

The performance of your shaker can significantly affect the overall efficiency and success of your material screening process. By understanding the factors that impact shaker performance and following best practices for maintenance and operation, you can ensure your equipment delivers maximum productivity. Fine-tuning vibration settings, selecting the right screen, and regularly maintaining the machine are all key steps toward optimal shaker performance.

With proper care and adjustments, a well-performing shaker can be a powerful asset, helping to improve product quality, minimize downtime, and boost throughput in any material processing operation.