1. Introduction: Quality Starts with Precision Screening

In modern construction, the performance of concrete depends on the precise formulation of cement, aggregates, and various additives. Whether it’s a high-strength bridge deck, a durable pavement, or a decorative architectural panel, the quality of every component matters.

Among these components, cement powders, mineral additives, and chemical admixtures must meet strict quality standards. Undersized or oversized particles, contamination, and moisture variations can compromise the uniformity of the mix, leading to weak points, inconsistent workability, or premature failures.

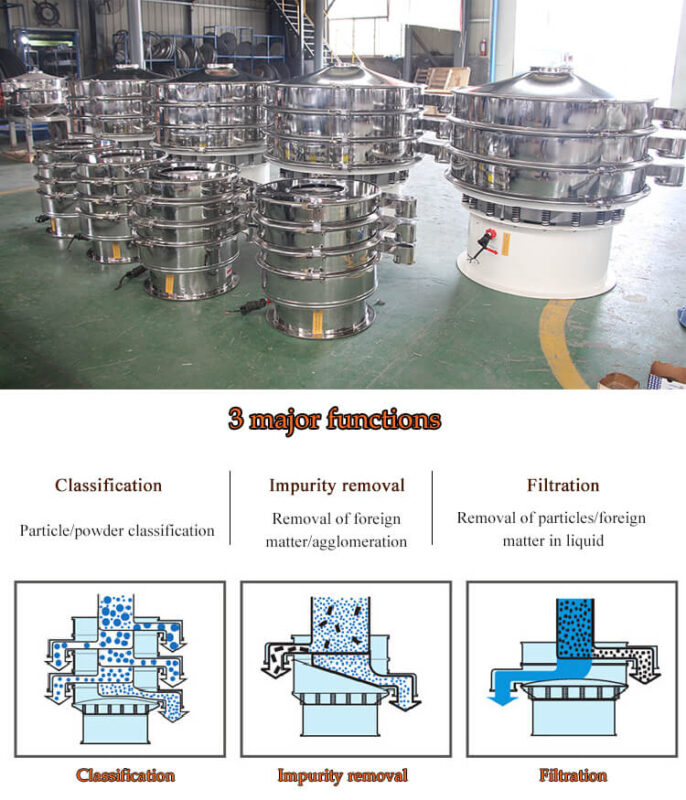

This is why vibrating screening technology plays a central role in cement and concrete additive processing. From powder classification to slurry filtration, modern screens ensure every batch meets the required performance criteria.

2. Industry Challenges in Cement & Additives Production

Cement and additive producers face several key challenges:

- 🧱 Fine powder control — Cementitious materials such as fly ash, silica fume, or ground slag require precise classification to meet particle size distribution (PSD) targets.

- 🌫 Dust & contamination — Cement powders generate significant dust and can be easily contaminated by foreign particles if not screened properly.

- 🧪 Additive uniformity — Chemical admixtures and mineral fillers must be accurately dosed and free of clumps or debris to ensure uniform mixing.

- ⚙️ Clogging & moisture issues — Fine powders can agglomerate, especially in humid environments, leading to blinding or uneven flow.

- 🏗 High-volume demands — Ready-mix plants and cement factories process hundreds of tons daily, requiring equipment that can handle continuous, heavy-duty operation.

- 🌍 Regulatory & performance standards — Modern construction projects must meet tight strength, setting time, and durability standards, leaving no room for material inconsistency.

Addressing these challenges requires robust, high-precision vibrating screens integrated into every stage of the material handling and preparation process.

3. Applications of Vibrating Screens in Cement & Concrete Additives

Vibrating screens are used in multiple stages of cement and concrete additive production, including raw material preparation, powder classification, admixture filtration, and final quality control.

a. Screening of Cement Powders & Supplementary Materials

Raw cement, fly ash, silica fume, ground granulated blast furnace slag (GGBFS), and limestone powder must be screened to remove oversized particles and foreign contaminants. High-frequency vibrating screens are especially effective at classifying these fine powders down to 100–200 μm, ensuring consistent fineness.

b. Classification of Mineral Additives

Mineral fillers like quartz flour, pozzolans, and microsilica require precise sizing to improve concrete performance. Proper screening improves strength development, workability, and long-term durability.

c. Screening Aggregates for Additive Blends

Some additives (like lightweight aggregates or expanded clay) are blended into cementitious mixes. Vibrating screens help classify these aggregates into tight size ranges, ensuring optimal packing density and mix homogeneity.

d. Filtration of Liquid Admixtures

Chemical admixtures, such as plasticizers, retarders, and accelerators, often contain undissolved solids. Vibrating screens equipped with fine mesh can act as in-line filters, removing impurities before dosing.

e. Final Product Quality Control

Before packaging or bulk loading, cement and additive powders are passed through vibrating control screens to catch any remaining contaminants, ensuring the final product is clean and uniform.

4. Key Advantages of Using Advanced Screening Equipment

Modern vibrating screening equipment offers several advantages over traditional sieving or rotary drum systems:

- ✅ High precision and consistency — Achieve narrow particle size distributions with minimal rejects.

- 🚀 High throughput — Handle large volumes of powder and aggregates continuously.

- 🧼 Improved cleanliness — Remove impurities and foreign materials effectively.

- 🛠 Low maintenance — Heavy-duty frames, modular decks, and self-cleaning meshes minimize downtime.

- 🌡 Better moisture control — High-frequency vibration prevents powder buildup, even in humid climates.

- 🌿 Dust control & safety — Enclosed systems with dust collection interfaces protect workers and meet environmental regulations.

5. Technological Innovations in Screening for Cement Applications

Recent advances in screening technology have made it possible to process ultra-fine powders and handle sticky or abrasive materials more efficiently:

- Ultrasonic-assisted vibrating screens for extremely fine cementitious powders

- Self-cleaning meshes that reduce blinding and maintain throughput

- Modular multi-deck systems that allow multiple classifications in one unit

- Integrated dust extraction and negative-pressure enclosures for clean plant environments

- Sensor-based monitoring systems that detect mesh wear and performance changes in real time

- Energy-efficient drives and lightweight frames to lower operating costs

These innovations make vibrating screens indispensable in modern cement and additive processing lines.

6. Case Example: Improving Cement Additive Fineness in a Malaysian Plant

A Malaysian concrete admixture manufacturer struggled with inconsistent particle size in their silica fume and fly ash blends. Their manual sieving method was slow, dusty, and often produced batches that failed lab tests.

They installed a high-frequency ultrasonic vibrating screen with a 200 μm mesh for final classification. The results were impressive:

- 📈 Improved product uniformity, with PSD deviations reduced by 70%

- 🧪 Consistent strength results in concrete mixes

- 🧹 Dust emissions cut by 60% thanks to enclosed design

- ⏱ Batch preparation time reduced by 40% compared to manual sieving

This upgrade not only improved product quality but also increased the plant’s overall output and worker safety.

7. Sustainability and Future Trends

The cement and concrete industries are under growing pressure to reduce carbon emissions, improve resource efficiency, and adopt smarter production methods. Screening technology plays a surprising but crucial role in this transition:

- 🌱 Efficient additive use — Better classification means less waste and more effective material use.

- 🌐 Smart screening — Sensors and AI are being integrated to adjust parameters automatically based on feed characteristics.

- 🧠 Closed-loop recycling — Returned concrete fines and dust can be reprocessed through vibrating screens, reducing landfill waste.

- ⚡ Energy optimization — Modern drives reduce power consumption while maintaining high screening performance.

As sustainability regulations tighten, precise, efficient, and clean screening systems will become even more essential to the cement and concrete additive supply chain.

8. Conclusion

Cement and concrete additive quality begins with effective screening. By integrating advanced vibrating screens at every critical stage — from raw material classification to final product control — producers can ensure their powders and additives meet strict performance standards.

This results in stronger structures, more durable concrete, and higher production efficiency, while also aligning with environmental and regulatory requirements.

Whether you’re processing fly ash, silica fume, chemical admixtures, or aggregates, modern screening technology is the backbone of high-quality concrete mixes.