Introduction: Turning Construction Waste into Valuable Resources

The global construction industry is growing at an unprecedented pace, generating massive volumes of construction and demolition (C&D) waste. This includes concrete rubble, bricks, asphalt, wood, glass, metals, and plastics. Without proper processing, these materials often end up in landfills, causing environmental damage and wasting recoverable resources.

Modern recycling technologies have changed this scenario. At the heart of these innovations lies vibrating screen equipment—a key solution for sorting, classifying, and processing C&D waste efficiently. By integrating advanced screening systems into recycling operations, companies can improve material recovery rates, reduce disposal costs, and support the circular economy.

The Growing Challenge of C&D Waste Management

Construction and demolition activities are among the largest sources of solid waste worldwide. According to global estimates, C&D waste accounts for up to 30–40% of total solid waste streams in many cities. This waste is highly heterogeneous—often contaminated, mixed, and difficult to handle.

Traditional methods like manual sorting or basic trommel screens are often inefficient for high-throughput operations. They can’t reliably separate materials of different sizes or handle sticky and abrasive waste efficiently. This is where vibrating screens outperform conventional methods, delivering precise sizing and separation even under challenging conditions.

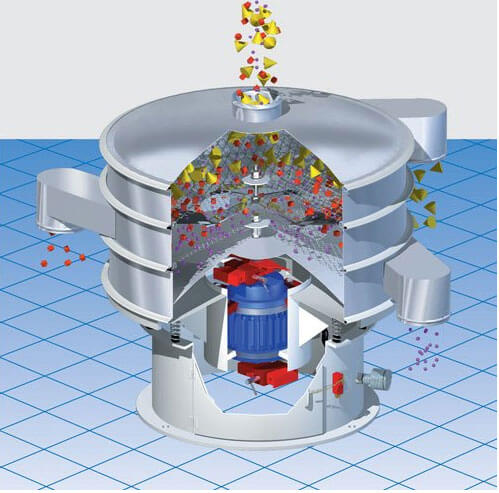

How Vibrating Screens Work in C&D Waste Processing

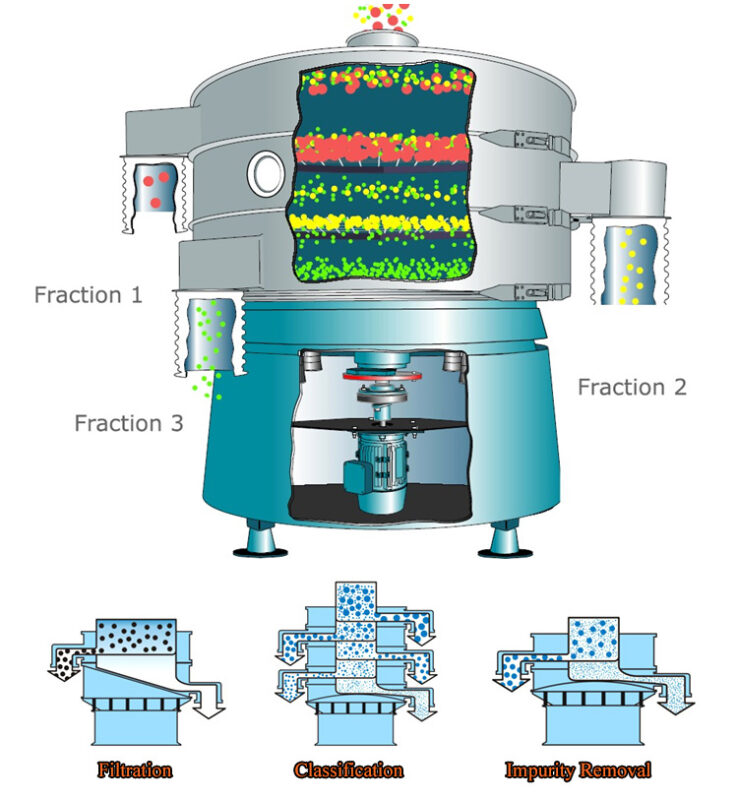

Vibrating screens use controlled vibration to separate materials based on particle size. When C&D waste is fed onto the screen deck, vibrations cause the material to stratify, allowing finer particles to pass through the mesh while larger particles move across the deck.

Key advantages of vibrating screens in this application include:

- High throughput capacity for handling large volumes of debris

- Accurate particle size separation, essential for producing reusable aggregates

- Versatility in processing mixed materials (concrete, soil, wood, metals, etc.)

- Low operational costs compared to manual labor or inefficient mechanical sorting

Different screen types (e.g., linear vibrating screens, circular screens, and high-frequency screens) can be tailored to suit different materials and processing goals.

Applications in C&D Recycling Plants

In modern C&D recycling facilities, vibrating screens are strategically integrated at multiple stages:

- Pre-Screening:

Before crushing or further processing, large debris and oversize materials are screened out. This protects crushers and improves efficiency downstream. - Size Classification:

After primary crushing, vibrating screens classify materials into different size fractions—coarse, medium, and fine. Each fraction can then be processed separately, e.g., coarse aggregates reused in road base, fine materials for backfilling. - Contaminant Removal:

Screens can effectively remove soil, dust, and light contaminants, improving the purity of recovered aggregates. - Final Product Screening:

To meet construction standards, the final recycled products are screened to precise size specifications, ensuring consistent quality for reuse in concrete or asphalt production.

Types of C&D Waste Suitable for Screening

Vibrating screens can handle a wide range of C&D materials, including:

- Concrete & reinforced concrete rubble

- Asphalt pavement

- Bricks, tiles, and ceramics

- Mixed soil and sand

- Glass fragments

- Wood and plastics (after separation)

By efficiently separating these components, recyclers can recover valuable resources such as reusable aggregates, clean fill materials, and secondary raw materials for manufacturing.

Benefits of Using Vibrating Screens in C&D Recycling

- Improved Recycling Rates

Vibrating screens enhance material recovery efficiency, enabling more waste to be diverted from landfills and reintroduced into construction cycles. - Cost Reduction

By separating valuable materials on-site, companies can lower transportation and disposal costs and generate revenue from selling recycled aggregates. - Regulatory Compliance

Many jurisdictions now mandate C&D waste recycling targets. Efficient screening helps companies comply with regulations while improving sustainability credentials. - Energy & Resource Efficiency

Reusing materials reduces the demand for virgin aggregates and minimizes the energy and emissions associated with quarrying and transportation. - Adaptability to Various Waste Streams

Whether dealing with mixed demolition debris or specific material streams, vibrating screens can be configured for different particle sizes, moisture levels, and production capacities.

Integrating Vibrating Screens into Sustainable Construction Strategies

C&D waste recycling is not just about waste management—it’s about closing the loop in the construction materials cycle. Vibrating screening equipment plays a critical role in this transition by making high-quality recycled aggregates a viable alternative to virgin materials.

When paired with crushers, magnets, air classifiers, and washing systems, vibrating screens form the backbone of integrated recycling lines that can process thousands of tons per day. This technology supports sustainable construction practices, reduces environmental impact, and creates new business opportunities for recyclers and contractors.

Conclusion: Building a Greener Future with Advanced Screening

The construction industry stands at the crossroads of growth and sustainability. By embracing vibrating screen technology for construction and demolition waste processing, companies can turn what was once a disposal problem into a valuable resource stream.

From pre-screening to final classification, vibrating screens deliver the efficiency, precision, and scalability needed to make C&D recycling a cornerstone of modern urban development. As cities continue to expand, these machines will play a key role in building a more circular and resource-efficient future.