In the world of large-scale construction, every detail matters, especially when it comes to raw materials like sand. Sand is the backbone of many construction processes, from concrete production to finishing plaster, and its quality can significantly impact the strength and longevity of a structure. However, achieving the required quality and consistency manually can be both time-consuming and error-prone. That’s where sand sieving machines come in.

These machines have revolutionized the way construction giants manage their sand supplies. By automating the sieving process, they ensure precision, save time, and reduce labor costs. More importantly, they help maintain consistency across large projects, which is crucial for meeting stringent construction standards. In this blog, I’ll delve into how sand sieving machines enhance efficiency, improve productivity, and ensure quality control in the construction industry, making them an indispensable asset for large-scale operations.

1. Benefits of Sand Sieving Machines

Precision in Material Sorting

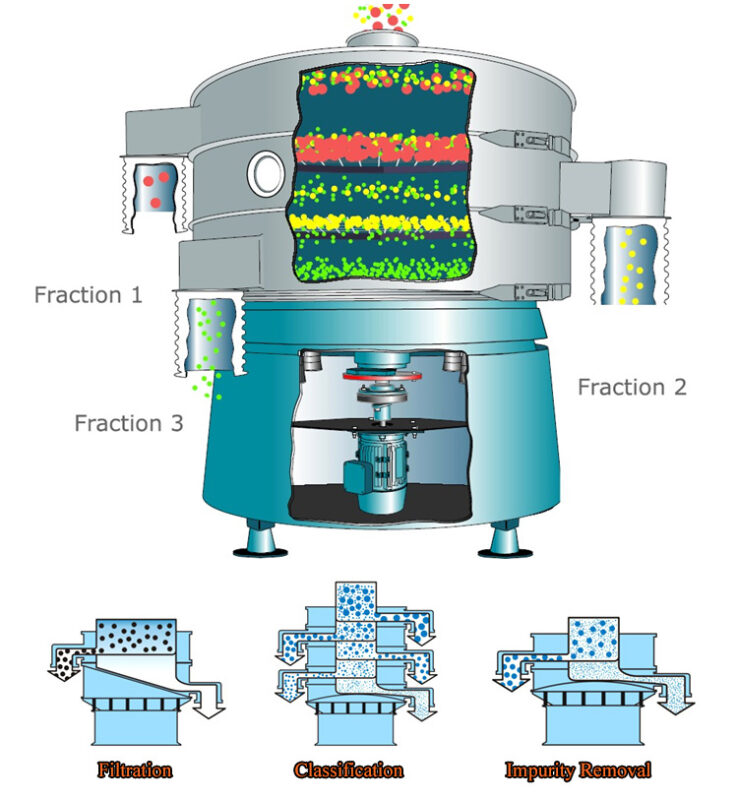

Sand sieving machines deliver unparalleled precision by separating sand into uniform sizes. In construction, uneven particle sizes can lead to issues in concrete strength and masonry quality. By using these machines, construction giants can ensure that every batch of sand meets project-specific requirements. The consistent output not only improves structural integrity but also reduces material rejections, saving time and resources.

Time and Labor Efficiency

Manually sieving sand is labor-intensive and prone to inconsistencies. Sand sieving machines automate this process, significantly reducing manual labor requirements. One machine can process large volumes of sand in a fraction of the time it would take a manual workforce. This efficiency allows teams to focus on other critical construction tasks, speeding up project timelines without compromising quality.

Waste Reduction

Sand sieving machines are excellent at separating reusable sand from debris and impurities. This capability minimizes material wastage and ensures that every usable particle contributes to the construction process. By reducing waste, these machines not only improve cost efficiency but also promote sustainable practices in the industry.

2. How Sand Sieving Machines Enhance Large-Scale Construction

Consistency in Material Supply

Large-scale construction projects require a constant and reliable supply of high-quality materials. Sand sieving machines ensure that construction teams receive uniformly sorted sand without interruptions. This consistency eliminates delays caused by material shortages or the need for additional processing, allowing projects to progress smoothly.

Adaptability to Project Needs

Different construction tasks demand varying sand grades. For example, fine sand is essential for plastering, while coarser grades are better suited for foundation work. Modern sand sieving machines can be adjusted to meet these diverse needs, providing tailored solutions for each phase of a construction project. Their versatility makes them indispensable for handling the complexities of large-scale operations.

Improved Productivity

By delivering high-quality sieved sand quickly and efficiently, these machines play a direct role in boosting overall productivity. Teams can complete tasks faster, meet project deadlines, and avoid costly overruns. The enhanced productivity translates into better project outcomes and increased profitability for construction businesses.

3. Choosing the Right Sand Sieving Machine

Capacity and Scalability

Construction giants often deal with massive volumes of sand daily. Selecting a sieving machine with the right capacity is critical to meeting project demands. High-capacity machines ensure that large-scale operations run smoothly, while scalable options allow businesses to adapt as project requirements grow.

Ease of Maintenance

Frequent maintenance can disrupt workflows and increase operational costs. When choosing a sand sieving machine, it’s essential to prioritize models that are durable and require minimal upkeep. Machines with robust construction and easily replaceable components offer better long-term value and fewer downtimes.

Trusted Manufacturers

The choice of manufacturer can make a significant difference in machine performance and reliability. Trusted vendors often provide cutting-edge models equipped with the latest technology, along with excellent customer support. Investing in machines from reputable manufacturers ensures better functionality, longer lifespan, and access to technical assistance when needed.

Sand sieving machines are more than just tools—they are catalysts for change in the construction industry. They streamline operations by delivering consistent, high-quality sand, saving time and resources while reducing waste. Their ability to handle large volumes and adapt to different project needs makes them essential for any construction giant aiming for efficiency and precision.

Investing in a reliable sand sieving machine not only boosts productivity but also ensures compliance with construction standards and enhances the overall quality of projects. For companies looking to stay competitive in today’s fast-paced construction landscape, these machines are not just an option—they are a necessity. Whether you’re laying a foundation or perfecting a finish, a sand sieving machine is your ally in achieving excellence.