Coal has been the backbone of industrial growth for centuries, powering everything from energy production to steel manufacturing. Its versatility and abundance make it a cornerstone resource for industries across the globe. However, raw coal straight from extraction is far from ready for industrial applications. It requires thorough processing to ensure the right size, quality, and composition for its intended use. This is where coal screening machines come into play, bridging the gap between raw extraction and refined excellence.

Coal screening machines are essential tools in modern industry, designed to sort, separate, and refine coal based on size and quality. By streamlining this critical process, these machines not only improve the efficiency of production lines but also reduce waste and costs. Whether you’re running a power plant, producing steel, or operating in cement manufacturing, the precision and reliability of a coal screening machine can transform your operations. In this blog, I’ll explore how these machines impact industrial processing, enhance efficiency, and help industries maintain sustainability while reducing operational costs.

1. The Role of Coal Screening Machines in Industrial Processing

Coal screening machines are the unsung heroes of industrial production, ensuring that raw coal meets the exact specifications required for different applications. These machines act as the gatekeepers of quality, sorting coal by size and removing impurities that can compromise performance. For example, power plants require specific coal grades to achieve optimal combustion, while steel manufacturers depend on the right size and consistency for efficient furnace operation. Without these machines, raw coal would often be too inconsistent to meet the stringent demands of industrial processes.

Beyond simple size separation, coal screening machines also enhance overall material handling. By streamlining the sorting process, they eliminate bottlenecks in production lines, reducing downtime and enabling higher throughput. This efficiency not only benefits producers but also ensures that end-users receive coal of uniform quality, leading to better performance and reduced maintenance needs in their own operations. Coal screening machines, therefore, play an essential role in transforming raw resources into high-value inputs for industrial use.

2. Innovations in Coal Screening Machines: Vibration and Ultrasonic Technologies

- 1. Vibration Technology

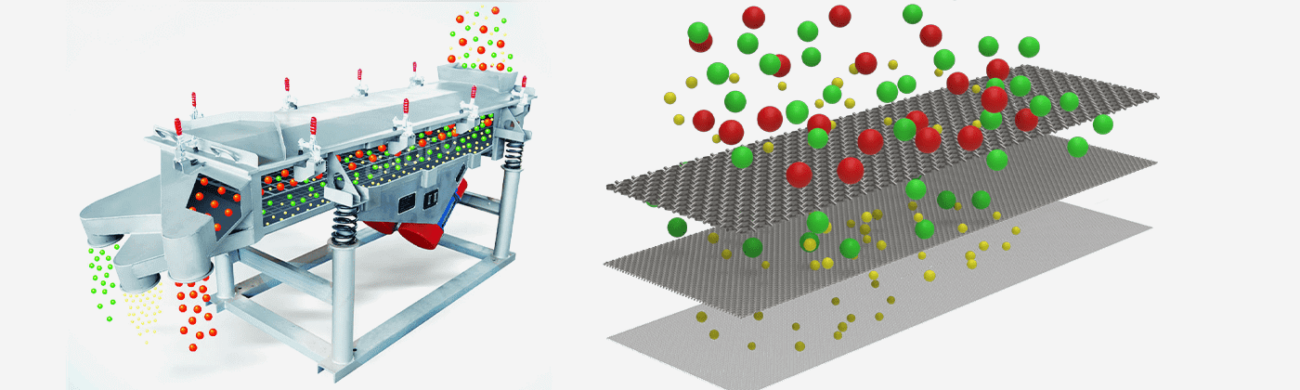

Vibration technology forms the backbone of modern coal screening machines. By applying high-frequency vibrations to the screening surface, these machines ensure that coal particles move efficiently across the screen and are accurately separated by size. The vibrations help prevent blockages by dislodging materials that might otherwise clog the screen openings, maintaining a continuous flow of coal.

The intensity and frequency of vibrations can be adjusted to accommodate different types of coal, from fine powders to large, irregular chunks. This adaptability allows producers to process various grades of coal with the same machine, enhancing operational flexibility. Furthermore, vibration technology minimizes wear and tear by evenly distributing the load across the screen, reducing maintenance costs and extending the machine’s lifespan.

- 2. Ultrasonic Technology

Ultrasonic technology takes precision and efficiency to a whole new level. By introducing high-frequency sound waves to the screening process, ultrasonic systems break down surface tension and improve the flowability of fine or sticky coal particles. This is especially beneficial for handling moist coal, which often clumps together and can be difficult to screen using conventional methods.

The ultrasonic vibrations create a micro-vibrating effect on the screen mesh, preventing particle adhesion and keeping the screen clean without manual intervention. This leads to more consistent screening results and reduces the frequency of shutdowns for cleaning or maintenance. Additionally, ultrasonic technology enhances the separation of ultra-fine coal particles, enabling producers to recover valuable material that might otherwise be wasted.

- 3. The Combined Advantage

When vibration and ultrasonic technologies are combined, they create a powerful screening solution capable of handling the most challenging coal processing requirements. These innovations allow machines to work faster, more accurately, and with greater efficiency, enabling large-scale producers to meet increasing demand while reducing operational costs.

Incorporating these technologies into coal screening machines reflects the industry’s commitment to innovation, productivity, and sustainability. By adopting these advanced solutions, producers can stay ahead in a competitive market and ensure their operations remain efficient and environmentally responsible.

3. How Modern Coal Screening Machines Adapt to Varying Coal Types and Moisture Levels

- 1. Adjustable Screening Parameters

Modern machines are designed with adjustable settings, allowing operators to fine-tune vibration intensity, frequency, and screen angle to match the specific properties of the coal being processed. For instance, harder coals may require stronger vibrations to break up clumps and ensure smooth movement across the screen, while softer coals can be handled with gentler settings to avoid over-fragmentation.

These adjustments ensure optimal separation efficiency, regardless of the coal type. Operators can easily switch between settings for different batches, making these machines ideal for facilities that process multiple grades of coal.

- 2. Specialized Screen Mesh Designs

Advanced screening machines come equipped with a variety of mesh options to suit different coal sizes and moisture conditions. For fine, powdery coal, ultra-fine meshes with anti-clogging properties prevent particles from adhering to the screen surface. For larger, lumpier coal, reinforced meshes ensure durability and prevent damage from heavy impacts.

Some machines even feature hybrid screen designs that combine multiple mesh types in a single unit. This allows producers to process a mix of fine and coarse coal simultaneously, maximizing efficiency and throughput.

- 3. Handling High Moisture Levels

Moisture is a common challenge in coal processing, as wet coal tends to clump together, reducing the effectiveness of traditional screening methods. Modern machines address this with advanced technologies like vibration and ultrasonic systems. Vibrations help dislodge wet clumps, ensuring smooth material flow, while ultrasonic waves break surface tension, preventing sticky particles from adhering to the screen.

Additionally, some machines are equipped with dewatering screens or integrated drying systems to reduce moisture content during screening. These features ensure that the processed coal meets quality standards, even when dealing with high-moisture raw materials.

Conclusion: The Future of Coal Processing with Modern Screening Machines

Modern coal screening machines have revolutionized the way industries process coal, offering unmatched adaptability, efficiency, and reliability. Their ability to handle diverse coal types and overcome the challenges posed by high moisture levels ensures that producers can maintain consistent quality while maximizing throughput. By integrating advanced technologies such as adjustable settings, specialized screen meshes, and smart automation, these machines have become indispensable tools for large-scale operations.

As the industry moves toward greater sustainability and efficiency, the role of advanced coal screening machines will only grow. They represent not just a technological upgrade but a step forward in creating smarter, more resource-efficient industrial practices. By investing in modern screening technology, producers are not only improving their operations today but also preparing for the challenges of tomorrow, ensuring long-term success in the ever-changing landscape of coal processing.