Cassava processing is a key part of agricultural production for many large-scale farmers, especially in countries where cassava is a staple crop. However, for producers working with significant volumes, the challenges of processing large amounts of cassava quickly and efficiently can be overwhelming. One of the most time-consuming steps in this process is sieving, where the material is separated into finer and coarser particles. Traditional manual sieving requires significant human labor, and the results can often be inconsistent, leading to wasted material and reduced quality.

1. The Labor-Intensive Nature of Traditional Sieving

In traditional cassava processing, manual sieving is a time-consuming and labor-intensive process that often requires a large workforce. Workers need to physically separate the finer particles from the coarser ones, a task that can take hours, especially when dealing with large batches. This method also results in inconsistent results, as different workers may apply varying levels of pressure or speed, affecting the uniformity of the sieved product.

Additionally, this method places a significant burden on labor costs. The more workers required, the higher the operational costs for large-scale producers. The need for continual supervision and training of workers adds to these costs. Moreover, manual labor poses challenges for scalability, as increasing production demands often require a proportional increase in the workforce, which can lead to inefficiency and logistical issues.

2. How Cassava Sieving Machines Streamline the Process

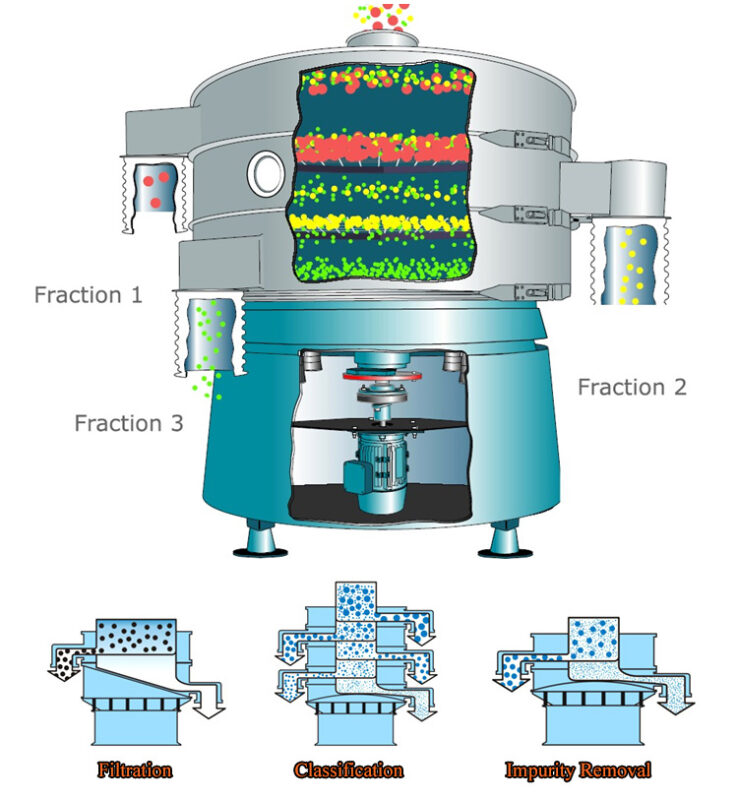

Cassava sieving machines offer a solution to the challenges of manual sieving. These machines automate the process, handling large volumes of cassava with precision and speed. Typically, these machines use vibration or rotary motion to separate the finer particles from the coarse ones, which ensures consistent sieving results across batches.

One of the primary advantages of these machines is their speed. Unlike manual sieving, which may take hours to complete a single batch, sieving machines can process much larger quantities in a fraction of the time. The automation of the sieving process also reduces human error, ensuring that each batch is sieved to the same standard. Machines can be operated continuously with minimal downtime, allowing producers to scale up their operations without the need to significantly expand their workforce.

3. Reducing Labor Costs and Improving Efficiency

By adopting cassava sieving machines, large-scale producers can significantly reduce their labor costs. The need for a large workforce is drastically minimized, as one or two operators can oversee several machines simultaneously, depending on the scale of the operation. This means fewer workers are required to handle the sieving process, which directly translates into savings on salaries, benefits, and training costs.

Furthermore, cassava sieving machines increase overall efficiency. The time saved through automation allows producers to process more cassava in less time, improving throughput and productivity. Because machines operate with high precision, they reduce waste and ensure that nearly all of the cassava crop is processed for use, increasing the yield per batch. The ability to process larger quantities with fewer errors also means less time spent on rework or sorting, which further boosts operational efficiency.

By reducing the need for manual labor and speeding up production, these machines help producers cut down on labor costs while enhancing productivity, leading to a more cost-effective and profitable operation.

In conclusion, cassava sieving machines are a game-changer for large-scale producers looking to improve labor efficiency and reduce costs. By automating the sieving process, these machines minimize the need for manual labor, which directly lowers operational expenses while boosting productivity. The consistency and precision they offer also ensure higher-quality products with less waste, further enhancing profitability. For producers aiming to stay competitive and meet growing demand, investing in cassava sieving machines is a smart decision that delivers long-term benefits, from improved efficiency to greater sustainability in production.