Finding the right sieve machine for your industry can feel overwhelming, especially when the options range from cassava sieving machines for agriculture to coal screening machines for mining or flour and sand sieves for food and construction. Each application comes with unique challenges, whether it’s achieving ultra-fine particle separation, maintaining high production efficiency, or ensuring durability in harsh environments.

In this guide, I’ll walk you through the essential factors to consider when selecting a commercial sieve machine tailored to your industry’s specific needs. From understanding the intricacies of cassava sieving machines to comparing coal screening options and exploring how flour sieves boost food production efficiency, I’ll cover it all. By the end, you’ll have the knowledge to make an informed decision that saves you time, money, and effort while enhancing your operational efficiency.

Let’s dive into the world of commercial sieve machines and discover how choosing the right one can transform your processes.

1.How to Determine the Ideal Cassava Sieving Machine for Agricultural Processing

When it comes to processing cassava, selecting the right sieving machine can significantly impact the quality of the final product and the efficiency of your operation. Cassava, a staple crop in many regions, requires precise handling to separate its various components, such as fine flour, fibers, and granules. The right sieving machine ensures this process is seamless, reducing waste and boosting productivity. Here’s a breakdown of the key considerations to guide your decision.

Capacity Requirements

The first step in choosing a cassava sieving machine is assessing your production needs. For small-scale farms or businesses, a compact machine with moderate capacity might suffice. However, if you’re operating a large agricultural processing facility, investing in a high-throughput machine is essential. Machines designed for industrial use can handle larger volumes of cassava without compromising on speed or efficiency. Knowing your daily or weekly production targets will help you select a machine that can keep up with demand.

Mesh Size Options

Mesh size is a critical factor in cassava sieving. Depending on the end product—whether it’s fine cassava flour for baking or coarser granules for other uses—you’ll need a machine with adjustable mesh options. A fine mesh is ideal for separating impurities and achieving a smooth flour consistency, while coarser meshes are better suited for granules or fiber removal. Machines that offer multiple mesh sizes or interchangeable screens provide versatility, making them suitable for diverse processing requirements.

Material Handling Features

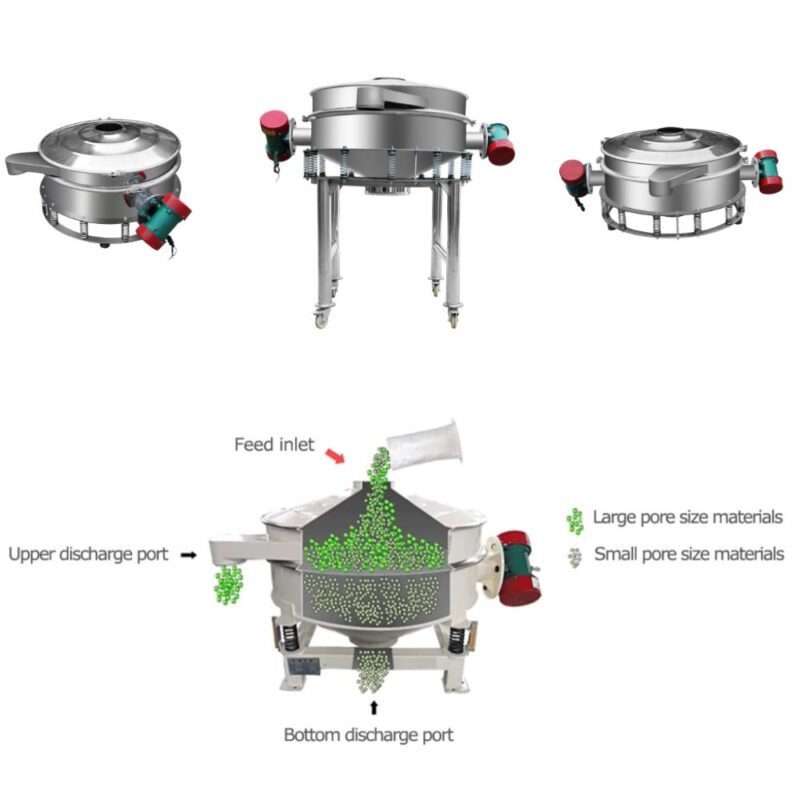

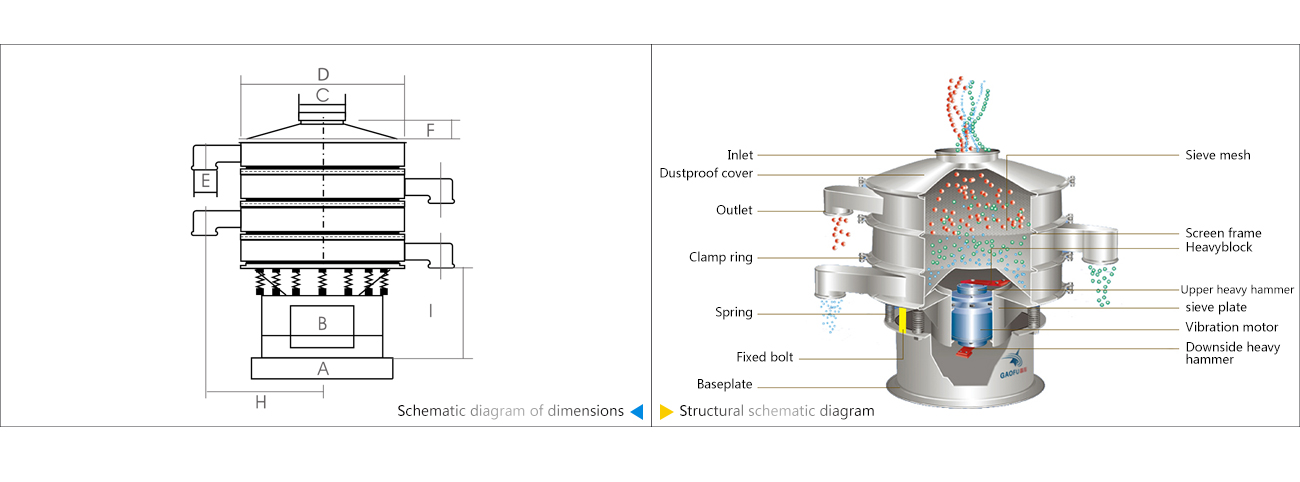

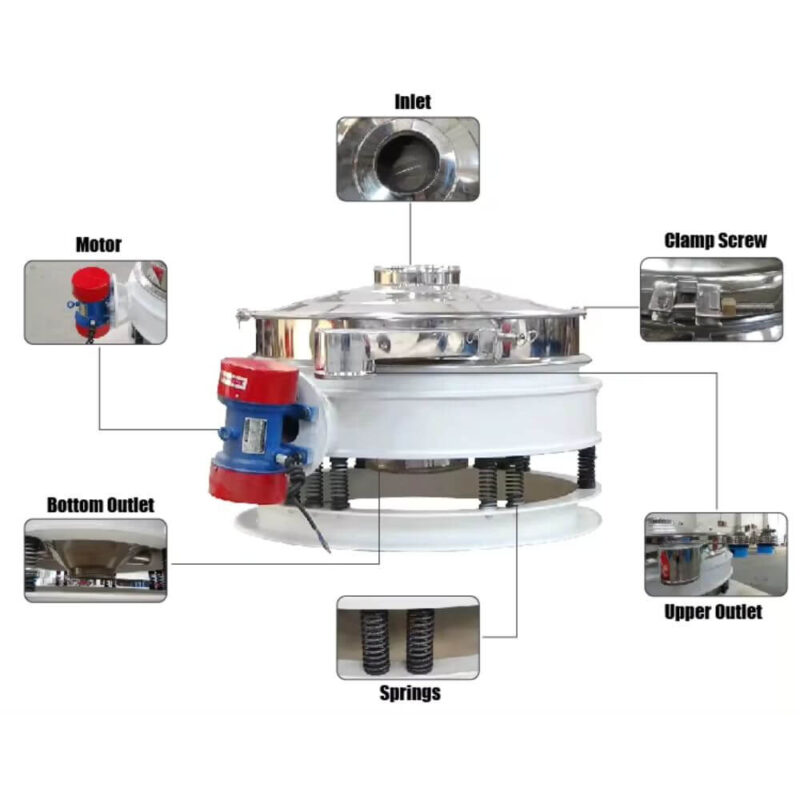

Cassava’s high starch content can pose challenges during sieving, as it tends to clump and clog traditional screens. Modern cassava sieving machines often include features like vibration technology, ultrasonic sieving, or rotary motion to prevent blockages. Self-cleaning mechanisms further enhance performance by keeping the sieves clear during operation, reducing downtime and labor costs. These advanced features are invaluable for ensuring continuous, efficient processing.

Durability and Maintenance

Cassava’s abrasive nature can wear down sieving components over time, especially if the machine is not built with durable materials. Stainless steel and other corrosion-resistant materials are ideal for prolonging the lifespan of the equipment. Additionally, machines designed with easy-to-replace parts make maintenance straightforward and cost-effective. Regular upkeep is essential to maintaining performance, so consider machines that simplify cleaning and repairs.

2.Comparing Coal Screening Machines: Finding the Best Fit for Your Mining Needs

Selecting the right coal screening machine is crucial for mining operations. Efficient screening ensures proper separation of coal by size, improves product quality, and enhances productivity. With various technologies available, it’s essential to understand the unique features, benefits, and applications of each type of machine. Let’s explore the key considerations to help you find the best fit for your mining needs.

Types of Coal Screening Machines

Coal screening machines come in various designs, each tailored to specific applications and operating conditions. Common types include:

- Vibrating Screens: These are widely used for coal screening due to their high efficiency and ability to handle large volumes. Vibrating screens use vibration to separate coal particles based on size, making them ideal for wet and dry screening processes.

- Trommel Screens: These rotating drum screens are best for separating fine particles from bulk material. They are particularly effective in handling sticky or moist coal.

- Banana Screens: Named for their curved design, these machines offer multiple screening angles in a single deck, providing high capacity and better stratification of coal particles.

Each machine has strengths and weaknesses, so understanding your material characteristics and production goals is vital in choosing the right type.

Capacity and Throughput Requirements

One of the primary considerations when selecting a coal screening machine is capacity. Large mining operations require machines capable of handling significant volumes of material efficiently. High-capacity vibrating screens or multi-deck systems are often the best choice for such operations. For smaller-scale operations, compact trommel screens may provide sufficient throughput without unnecessary energy consumption.

Screening Accuracy and Efficiency

Accuracy in coal screening directly impacts the quality of the final product. Machines with adjustable mesh sizes or multi-deck configurations allow for precise separation of particles into different size fractions. Vibrating screens, for instance, are known for their high accuracy, while trommel screens are better suited for rougher separations where precision isn’t as critical. Choose a machine that aligns with your product quality standards and customer specifications.

Durability and Operating Environment

Coal screening machines must endure harsh mining conditions, including abrasive materials, heavy loads, and exposure to moisture. Durability is essential to minimize downtime and maintenance costs. Machines constructed with heavy-duty steel frames and corrosion-resistant components are ideal for these environments. For wet screening, look for screens with anti-clogging mechanisms to ensure consistent performance.

Energy Consumption and Operational Costs

Energy efficiency is a growing concern in mining, given rising fuel and electricity costs. Modern coal screening machines often include features like energy-efficient motors or variable frequency drives that optimize power usage. Trommel screens, for instance, generally consume less power than vibrating screens, making them suitable for operations with lower throughput demands. Balancing energy efficiency with operational requirements can significantly reduce costs over time.

Maintenance and Ease of Use

Maintenance plays a significant role in the long-term performance of coal screening machines. Systems with easy-to-replace parts and straightforward cleaning procedures reduce downtime and keep operations running smoothly. Machines with modular designs allow for quick repairs, minimizing interruptions in production. Additionally, automated features like self-cleaning screens can further simplify maintenance tasks.

3.The Role of Flour Sieve Machines in Enhancing Food Production Efficiency

Flour sieve machines are indispensable in food production, where precision and efficiency are essential for maintaining quality standards. These machines ensure the consistent processing of flour by removing impurities, separating particles by size, and improving overall product texture. From bakeries to large-scale food manufacturing facilities, investing in a reliable flour sieve machine directly impacts production speed and product quality. Let’s delve into how these machines elevate food production efficiency.

Ensuring Uniformity and Consistency in Flour Quality

Uniform particle size is a cornerstone of high-quality flour production. Flour sieve machines excel in achieving this by separating fine flour from coarser particles and contaminants. A consistent texture ensures even mixing and baking, which is critical for bread, cakes, and other baked goods. For manufacturers, this means fewer production errors and greater customer satisfaction.

Flour sieve machines often come with adjustable mesh sizes, allowing for customization based on the specific requirements of different recipes. Whether you need superfine flour for delicate pastries or coarser flour for artisanal bread, these machines can cater to diverse needs without compromising quality.

Streamlining Production Processes

In large-scale food production, efficiency is a top priority. Flour sieve machines speed up the sieving process, which would otherwise require significant manual labor. Automated machines can process large volumes of flour quickly, ensuring uninterrupted production lines and meeting high-demand schedules.

The integration of vibratory technology in modern flour sieve machines enhances speed and precision. Vibrations facilitate the quick movement of flour through sieves, reducing clogs and ensuring smooth operation. This not only boosts productivity but also minimizes downtime, making the entire process more cost-effective.

Reducing Waste and Contamination Risks

Food safety is non-negotiable in any production setting. Flour sieve machines play a vital role in ensuring safety by removing foreign particles, lumps, and contaminants from the flour. This is particularly important in preventing allergens or non-food materials from entering the final product.

Advanced machines are designed with hygienic features, such as stainless steel construction and easy-to-clean components. Some even include dust covers, which prevent contamination during the sieving process. By maintaining a clean processing environment, these machines help producers comply with strict food safety regulations and standards.

Catering to Diverse Production Needs

One of the most significant advantages of flour sieve machines is their versatility. They can handle a wide range of flour types, from wheat and rice flour to specialty options like almond or coconut flour. This adaptability makes them a valuable investment for manufacturers producing diverse food products.

For smaller-scale operations, compact machines provide high efficiency without taking up excessive space. On the other hand, large industrial-grade sieve machines can manage bulk production, ensuring consistency and speed across multiple shifts. This scalability ensures that businesses of all sizes can benefit from this technology.