In pharmaceutical manufacturing, achieving the highest standards of purity and efficiency isn’t just a goal; it’s a necessity. Every step in the production process impacts the safety, efficacy, and quality of the drugs produced. Yet, traditional methods of sieving and separation often struggle to meet the increasing demands of modern production lines. Issues such as inconsistent particle sizes, contamination risks, and bottlenecks in production can compromise the entire operation.

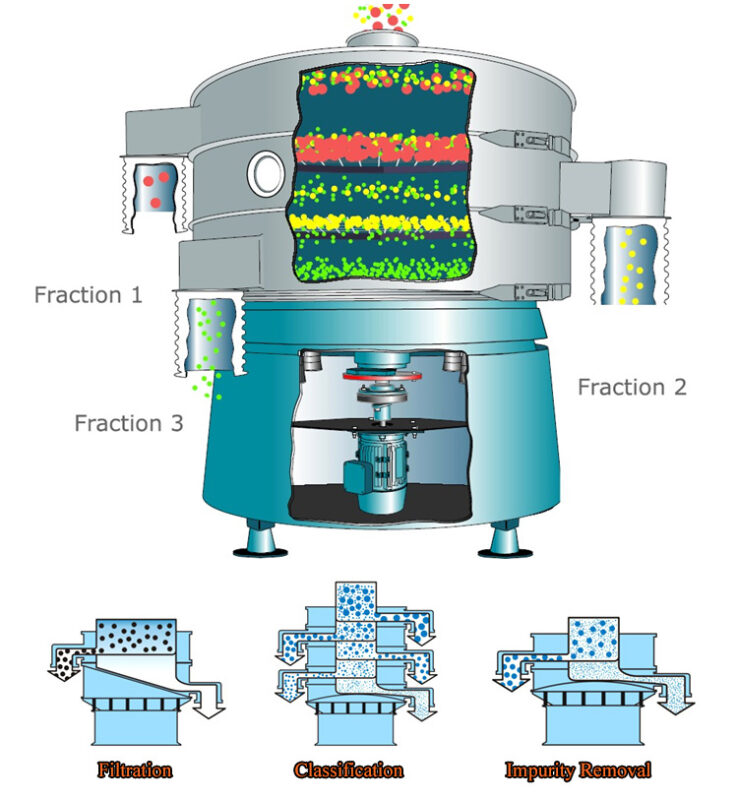

Vibratory separators have emerged as a transformative solution. These advanced machines streamline production, ensuring consistency, precision, and compliance with stringent regulatory standards. Whether for sieving powders, sorting granules, or removing impurities, vibratory separators are becoming indispensable in drug manufacturing.

1. Features of Advanced Vibratory Separator Technology

- Precision Engineering

Modern vibratory separators are designed for unparalleled precision. Adjustable settings, such as vibration amplitude and frequency, allow operators to fine-tune the machine for optimal performance. This level of control ensures that only materials meeting the required specifications pass through, eliminating errors and waste.

The precision offered by these machines is particularly valuable in handling sensitive active pharmaceutical ingredients (APIs). Even slight deviations in particle size can impact drug efficacy. Vibratory separators address these challenges by delivering highly accurate and reliable results, ensuring that every ingredient meets exacting standards.

- Versatility in Applications

One of the standout features of vibratory separators is their ability to handle a wide range of materials. Whether working with fine powders, coarse granules, or sensitive active pharmaceutical ingredients (APIs), these machines adapt seamlessly to different requirements. This versatility makes them ideal for diverse production needs.

In addition to handling different material types, modern separators can integrate with existing production lines. This adaptability ensures that manufacturers can upgrade their equipment without overhauling their entire process, saving both time and resources.

2. Applications of Vibratory Separators in Large-Scale Drug Manufacturing

- Powder Sieving

In the initial stages of drug production, vibratory separators play a vital role in sieving raw materials like APIs and excipients. By ensuring uniform particle sizes, these machines facilitate better mixing and formulation, leading to consistent results in the final product.

Uniform powders are easier to blend, ensuring that each dose contains the exact proportions of active and inactive ingredients. This step is critical for maintaining the therapeutic efficacy of medications and reducing variability between batches. For large-scale operations, the ability to sieve significant quantities of powder efficiently is a game-changer.

- Tablet Production

Tablet manufacturing relies heavily on precise blends of ingredients. Vibratory separators ensure that all materials used in tablet compression are free from impurities and meet the required size specifications. This step is crucial for producing tablets that dissolve correctly and deliver the intended dosage.

The role of vibratory separators extends beyond sieving. Their ability to operate continuously without clogging or slowing down makes them ideal for high-speed tablet production lines. By maintaining a steady supply of perfectly sized materials, these machines ensure uninterrupted production and high output rates.

- Capsule Filling

For capsule production, material uniformity is key to ensuring proper filling and dosage accuracy. Vibratory separators prepare materials with the exact consistency needed for smooth capsule-filling operations, minimizing rejects and maximizing output.

Capsule filling machines rely on precise weight and volume measurements to ensure consistency. Vibratory separators enable this by delivering uniform and contaminant-free materials, creating a foundation for accurate and reliable production. This consistency reduces the need for rework and boosts overall productivity.

3. Choosing the Right Vibratory Separator for Your Needs

Capacity Considerations

When selecting a vibratory separator, capacity is one of the most important factors to consider. Manufacturers should evaluate their production scale and choose a machine capable of handling their throughput requirements without compromising efficiency or precision.

High-capacity machines are particularly beneficial for large-scale operations, where delays can have a cascading impact on the supply chain. Investing in a machine that meets or exceeds production demands ensures smooth operations and future-proofing for potential scale-ups.

Customization Options

Modern vibratory separators come with various customization options, such as multi-deck designs for simultaneous separation of different material grades and ultrasonic technology for handling ultra-fine powders. These features allow manufacturers to tailor the machine to their specific needs.

Customizable separators also enable integration with automated systems, enhancing overall production efficiency. By choosing a machine with the right combination of features, manufacturers can address unique challenges and optimize their processes.

Vendor Reputation and Support

Investing in a vibratory separator is a long-term commitment. It’s essential to choose a reliable vendor with a track record of quality and excellent customer support. Reliable vendors provide ongoing maintenance, training, and technical assistance to ensure smooth operations.

A trusted vendor also ensures that spare parts are readily available, reducing downtime in case of maintenance or repairs. Comprehensive after-sales support is a critical factor in maximizing the lifespan and performance of the equipment.

Vibratory separators are redefining pharmaceutical manufacturing by delivering unmatched levels of purity, precision, and efficiency. From enhancing production speed to ensuring regulatory compliance, these machines address the unique challenges of large-scale drug production. Their advanced features, including hygienic design and customizable options, make them indispensable in modern facilities.

For manufacturers aiming to stay competitive and meet the demands of an ever-evolving industry, investing in vibratory separators is a strategic move. By embracing this technology, companies can achieve superior product quality, reduce operational costs, and maintain compliance with global standards, all while setting new benchmarks for efficiency and excellence in pharmaceutical production.