When it comes to matcha, the key to its exceptional quality lies in the finer details of the manufacturing process. From leaf harvesting to grinding, every stage contributes to the final product. One crucial yet often overlooked step in the production of premium matcha is sieving. The importance of sieving in maintaining smooth texture, flavor consistency, and overall quality cannot be overstated.

In this blog, we’ll explore how sieving machines are transforming the matcha manufacturing process, ensuring that each batch of matcha powder meets the highest standards of purity, flavor, and appearance.

1. What is Sieving and Why It Matters in Matcha Production?

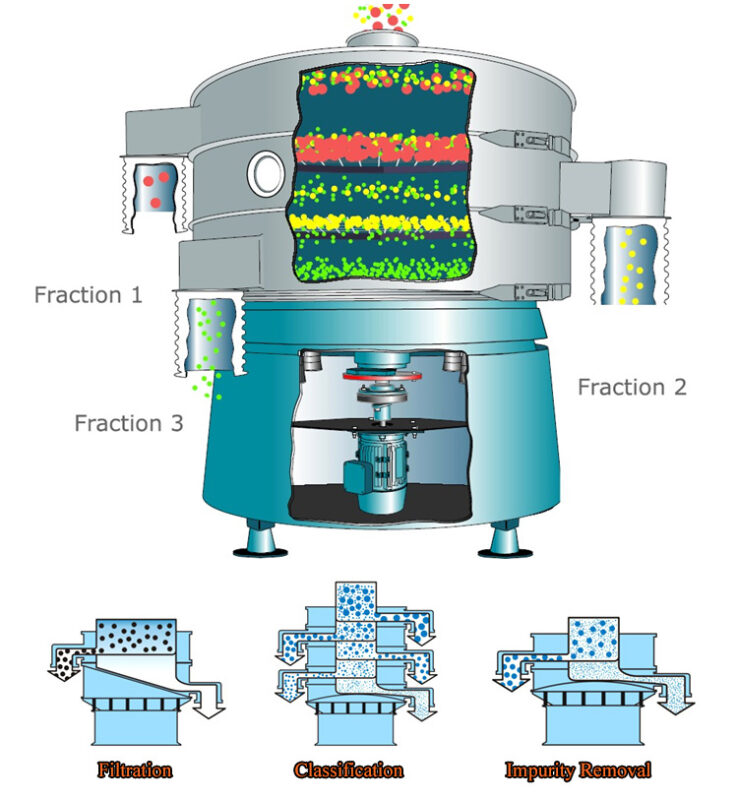

Sieving is the process of separating particles of different sizes to ensure consistency in the final product. In matcha production, this means filtering out larger particles, fibers, and dust from the finely ground matcha powder to leave only the finest, smoothest particles. The role of sieving machines in this process is to refine the powder and guarantee a superior product that meets both consumer expectations and industry standards.

- Achieving a Smooth, Silky Texture:

Matcha that has been properly sieved is free of clumps and particles, giving it a smooth, creamy texture when mixed with water. This is essential for a premium tea-drinking experience. - Maintaining Purity:

Sieving removes unwanted fibers, stems, and impurities, leaving behind pure matcha powder that enhances the flavor and visual appeal. - Ensuring Consistency:

Sieving ensures that each batch of matcha is of uniform quality, which helps create a consistent flavor profile and color every time a consumer brews their matcha.

2. The Challenges of Traditional Sieving Methods

Before the introduction of sieving machines, matcha manufacturers relied on manual sieving techniques, which came with their own set of challenges.

- 1. Labor-Intensive Process

Manual sieving is time-consuming and requires skilled labor. For large-scale matcha production, this approach becomes inefficient and costly.

- 2. Inconsistencies in Results

Human error during manual sieving can result in inconsistencies in particle size, leading to uneven texture and flavor in the final matcha powder. This can lead to customer dissatisfaction.

- 3. Scaling Issues

As demand for high-quality matcha increases, it becomes increasingly difficult to maintain the same level of quality with traditional methods. Scaling up production while ensuring premium quality becomes a major challenge.

3. How Sieving Machines Improve Matcha Quality

Modern sieving machines are a game-changer for matcha manufacturers. These machines automate the sieving process, ensuring consistency, speed, and high-quality results that manual methods cannot match.

Advanced Sieving Technology

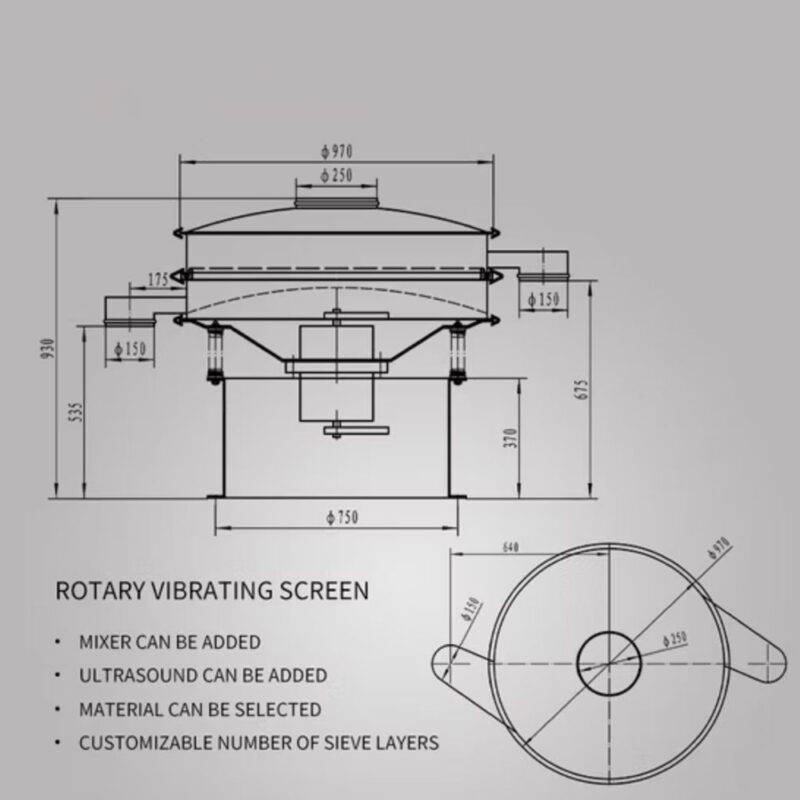

Sieving machines are designed to deliver precise and consistent results, ensuring the best matcha powder every time. Key features include:

- Multiple Mesh Layers: Sieving machines use several layers of mesh to separate matcha powder into different grades, ensuring that only the finest particles remain. This helps in delivering premium quality, with the right texture and purity.

- Adjustable Settings: Many sieving machines offer adjustable settings to cater to different matcha types and grades. This means manufacturers can tailor the sieving process to produce fine matcha, ceremonial-grade matcha, or other varieties with specific characteristics.

- Vibration and Pressure Mechanisms: These machines utilize vibration and pressure to sift the matcha more efficiently, ensuring a consistent texture and uniform particle size across large batches.

Benefits of Sieving Machines for Matcha Manufacturers

The adoption of sieving machines brings a host of benefits to matcha manufacturers, both in terms of product quality and operational efficiency.

- 1. Superior Texture and Consistency

Sieving machines ensure that matcha powder has a smooth, lump-free texture, which is essential for achieving that perfect matcha latte or bowl of tea. With consistent particle sizes, every batch of matcha has the same silky smooth finish.

- 2. Enhanced Purity

By effectively removing impurities, stems, and fibers, sieving machines guarantee a cleaner, purer product. This is crucial for maintaining the premium status of matcha and satisfying consumer expectations for purity.

- 3. Increased Efficiency and Scalability

Automating the sieving process allows manufacturers to increase their production capacity without compromising quality. Sieving machines can process large quantities of matcha quickly, ensuring that businesses can scale up their operations to meet growing demand.

- 4. Cost Savings

Though the initial investment in sieving machines may seem high, they save money in the long run by reducing labor costs and material waste. Additionally, machines that remove impurities prevent wasted product, improving overall profitability.

- 5. Improved Flavor and Aroma

A well-sieved batch of matcha has a more balanced, richer flavor and aroma. With consistent particle size and purity, manufacturers can ensure that each cup of matcha offers the same enjoyable taste and fragrance.

How to Choose the Right Sieving Machine for Matcha Production

Choosing the right sieving machine is essential to ensuring that your matcha meets the highest standards of quality. Here are some key factors to consider when selecting a sieving machine for matcha production:

- 1. Capacity and Volume Needs

Consider the scale of your operation. Larger-scale manufacturers should look for machines that can handle high volumes of matcha efficiently, while smaller operations may prefer more compact models.

- 2. Adjustable Mesh Options

Look for sieving machines that allow you to adjust the mesh size. Matcha grades vary in fineness, and having the ability to change mesh size lets you customize your product according to different market demands.

- 3. Durability and Maintenance

Choose a machine made from high-quality materials that can withstand continuous use. Ease of maintenance is also important to ensure that the machine remains in good working condition over time.

- 4. Automation Features

Automated sieving machines reduce the need for manual labor, allowing you to focus on other areas of production. Machines with automated features, such as vibration control and dust collection, ensure efficiency and cleanliness in the production process.

Case Study: How One Matcha Manufacturer Improved Quality and Output

A leading matcha manufacturer was facing challenges with inconsistent product quality and slow production times. The company adopted a state-of-the-art sieving machine, which significantly enhanced their matcha quality.

- Improved Product Quality: The sieving machine removed all impurities and ensured uniform particle size, resulting in a smoother texture and better flavor.

- Increased Production Efficiency: With automation, the company saw a 30% increase in production speed.

- Cost Reduction: By reducing material waste and labor costs, the manufacturer was able to boost their profit margins while maintaining high-quality matcha.

This case study highlights how adopting advanced sieving technology can drastically improve both the quality and efficiency of matcha production.

Sieving machines are an essential investment for matcha manufacturers committed to producing the highest-quality products. By automating the sieving process, these machines ensure superior texture, purity, and consistency in every batch of matcha, making them a must-have for manufacturers looking to stay competitive in the market.

Investing in a high-quality sieving machine is the first step toward achieving perfection in your matcha manufacturing. Whether you’re scaling up production or simply improving the quality of your matcha, the right sieving technology can help you achieve the premium results your customers expect.

For perfect matcha every time, make sieving machines a core part of your production process.