In the world of rose petal production, whether for cosmetic, culinary, or medicinal purposes, quality and purity are paramount. For manufacturers aiming to deliver the finest products, sieving technology plays a critical role in ensuring consistency, efficiency, and the highest quality standards. The introduction of advanced sieving machines has revolutionized the way rose petals are processed, allowing manufacturers to meet the ever-increasing demand for refined and contaminant-free products. This blog will explore the essential role of sieving machines in perfecting rose petal manufacturing, and why they are indispensable to the industry.

1. Enhancing Purity and Consistency

Purity and consistency are two of the most critical factors for rose petal manufacturers. Since the rose petal industry serves diverse sectors like cosmetics, pharmaceuticals, and food, customers expect products that are not only of superior quality but also free from contaminants. Impurities such as dirt, dust, twigs, or even foreign petals can undermine the quality and marketability of the final product.

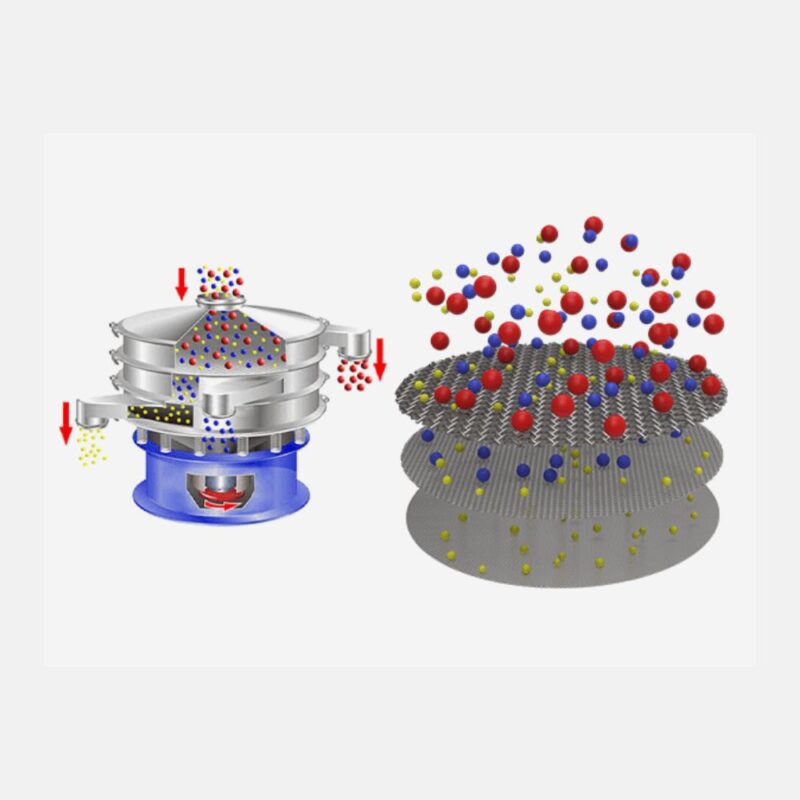

Sieving machines play an indispensable role in ensuring that these impurities are effectively separated, preserving the overall quality. These machines are equipped with precision sieves that filter out even the smallest contaminants, making sure that the petals remain pure, intact, and ready for use in the next production stage. Additionally, sieving machines can perform this task at scale, handling large quantities of petals efficiently, which would otherwise be a highly labor-intensive task.

By providing consistent and clean materials every time, sieving machines offer a crucial advantage to manufacturers, as it allows them to meet regulatory standards and quality benchmarks with ease. In industries such as skincare, where purity is paramount, the ability to deliver a flawless product is non-negotiable, and sieving machines ensure that every batch meets the highest standards of cleanliness and consistency.

2. Improving Efficiency and Reducing Waste

For any manufacturer, operational efficiency and reducing waste are key drivers of profitability. Traditional methods of sorting and sieving rose petals are slow, labor-intensive, and prone to human error. Manual processes often result in wasted petals or contamination, leading to higher production costs and less-efficient operations.

The advent of automated sieving machines has revolutionized this process. With their ability to handle large quantities of petals in a short amount of time, sieving machines have significantly improved production speed and efficiency. What would take hours to achieve manually can now be done in a fraction of the time, allowing manufacturers to scale up production without sacrificing quality. The high throughput of sieving machines ensures that manufacturers can meet the demands of a growing market.

Furthermore, these machines help reduce waste by efficiently separating broken or fragmented petals from intact ones. The ability to capture and redirect small, valuable fragments back into the production cycle ensures that no material is wasted, further boosting the yield. Over time, the operational efficiencies gained through automated sieving result in cost savings and higher profit margins, which make sieving machines an essential investment for any rose petal manufacturer.

3. Preserving the Integrity of Rose Petals

Rose petals are delicate by nature, and maintaining their structural integrity is a significant challenge during the sieving process. Whether the goal is to extract essential oils, produce rose water, or dry petals for cosmetic use, it’s crucial to preserve the natural structure of the petals. Damaged petals can negatively affect the aesthetic and functional properties of the final product.

Advanced sieving machines are designed with this in mind, featuring gentle yet effective mechanisms that preserve the integrity of the rose petals. With features such as low-vibration screens and controlled sieving speeds, these machines minimize mechanical stress on the petals, reducing the likelihood of breakage. The precise control over how petals are sieved ensures that only the finest, most intact petals are processed further.

By using sieving technology, manufacturers can ensure that their products retain the quality and characteristics customers expect. Whether the product is intended for high-end cosmetics or high-value food products, the ability to maintain the original quality of the rose petal is essential. Sieving machines provide a controlled environment in which the petals are separated efficiently while maintaining their natural properties.

4. Customization for Different Applications

One of the standout benefits of modern sieving machines is their adaptability. Not all rose petal products require the same level of purity or grading. For instance, dried rose petals used in aromatherapy may require a different sieving process than petals intended for the food or cosmetic industry. Some applications may require finely sifted powder, while others may need whole, intact petals.

Sieving machines are equipped with customizable features that allow manufacturers to adjust sieve sizes, vibration intensity, and processing speeds according to the specific requirements of the application. This flexibility means that a single sieving machine can serve a variety of purposes, from fine filtration of rose petal powder to grading petals into different sizes for various uses.

This adaptability ensures that manufacturers can produce a range of products from the same batch of raw material without having to invest in separate processing equipment for each. This reduces operational costs and space requirements while ensuring high-quality outcomes. Whether producing luxury skincare products, gourmet teas, or essential oils, the versatility of sieving machines ensures that manufacturers can meet the demands of each unique market.

Conclusion

Sieving machines have truly transformed rose petal manufacturing, offering manufacturers an indispensable tool for ensuring purity, consistency, efficiency, and product integrity. By automating the sieving process, these machines not only improve production speed but also allow for greater quality control, reducing waste and enhancing profitability. Furthermore, the adaptability of modern sieving technology ensures that manufacturers can meet the unique demands of different applications, from cosmetic-grade petals to those used in culinary products.

As demand for high-quality rose petal products continues to grow across various industries, sieving machines will remain at the forefront of ensuring that manufacturers can deliver the best possible products to their customers. Investing in advanced sieving technology is not just a strategic move for improving efficiency but also a commitment to delivering high-quality products that meet consumer expectations and industry standards. With sieving machines, rose petal manufacturers can confidently stay ahead of the competition, driving growth and innovation in this rapidly evolving market.

4o mini