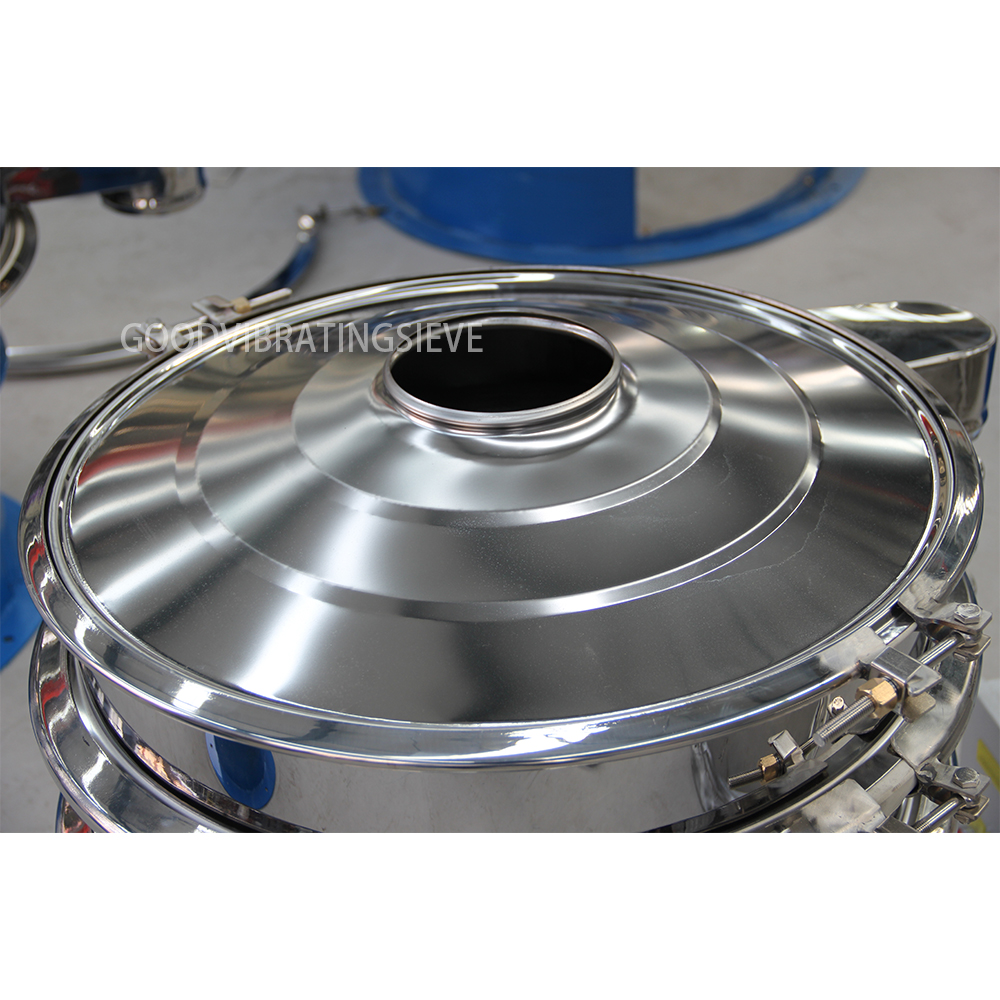

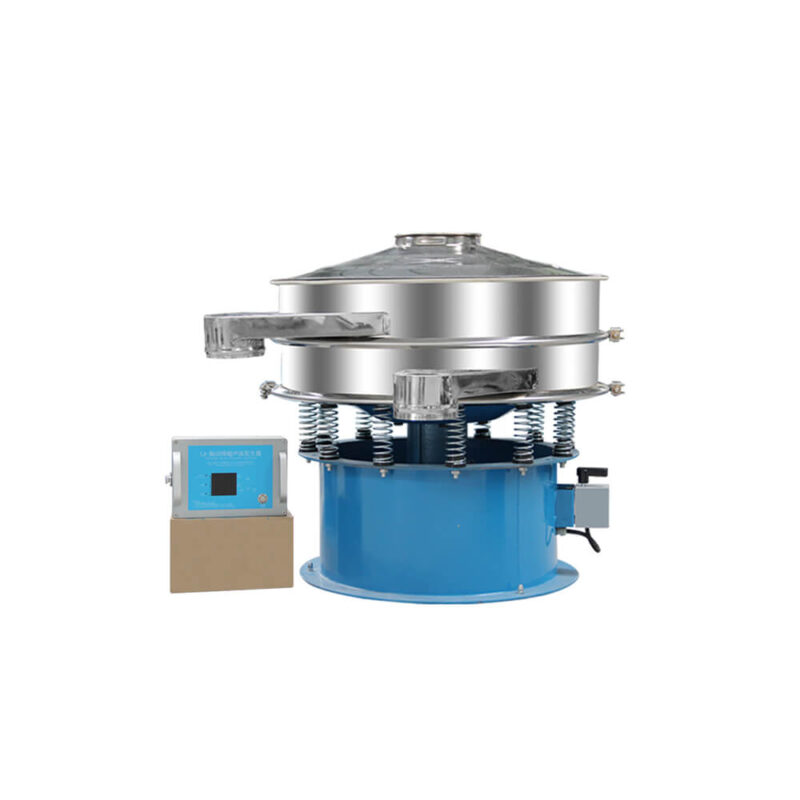

UltraSpin Rotary Vibrating Screen Separator

Machine material: Full SUS304, Contacting Material Steel SUS304

Layer: 1-8

Diameter of screen(mm):200-2000

Mesh size: 2.5-1250 mesh

Power(KW): 0.25-3 kw

Price ($):500-3000

Application: Powder, Granules, Liquid, Bulk Solids and other ingredients

Customize service: All parts can be customized

-

Official retailer

-

Quality guaranteed

-

Free delivery from $99

-

Free returns is available

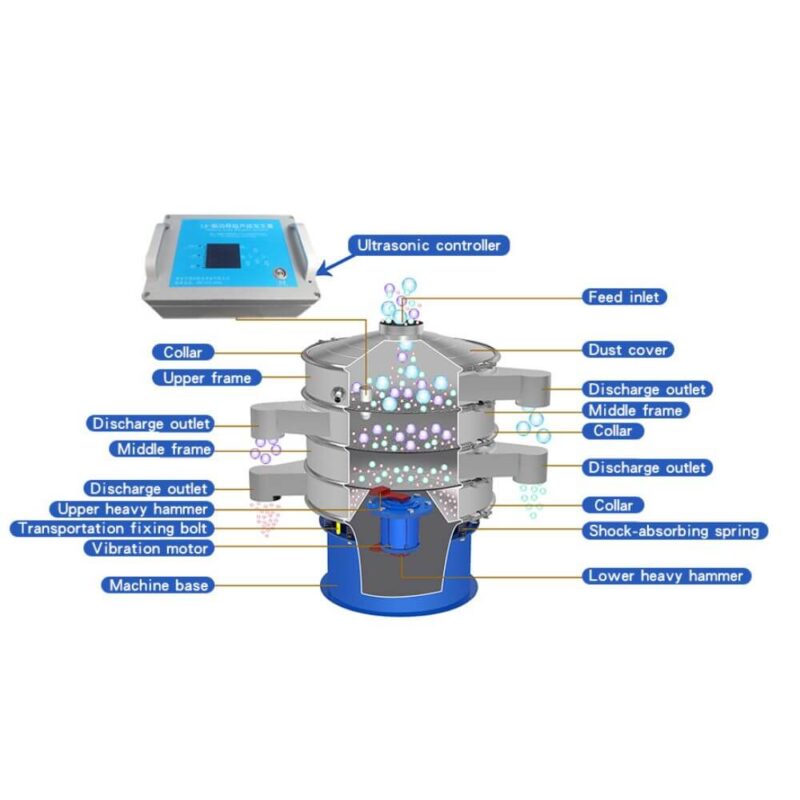

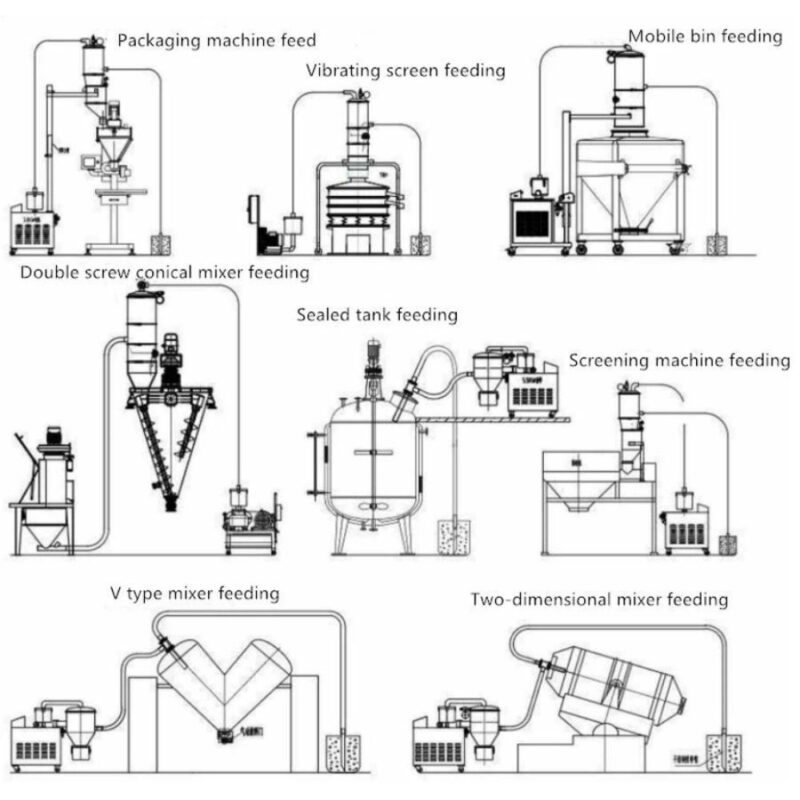

This advanced machine incorporates ultrasonic technology to enhance vibration, ensuring thorough and accurate screening of fine powders. Ideal for industries such as pharmaceuticals, food processing, and chemicals, the UltraSpin delivers consistent performance and high throughput. Its robust construction and easy-to-clean design make it a reliable and durable choice for any production line. Elevate your powder separation processes with the UltraSpin – where cutting-edge technology meets superior efficiency.

Jane –

We use this vacuum feeder for coffee beans, and it’s been a fantastic investment. It transports beans gently and efficiently, ensuring they reach the next stage of production in perfect condition.

Thompson –

This vacuum feeder is perfect for our wheat processing. It transports grain efficiently, ensuring a steady flow and reducing manual handling. The machine is easy to clean and highly reliable.

Sophia –

We use this vacuum feeder for moving sunflower seeds, and it’s fantastic.

Harris –

For our gravel sorting needs, this vibrating screen is unmatched. It separates different sizes effortlessly, even under heavy loads. The machine is durable and handles continuous operation without any issues.

Joseph –

In our coffee bean grading process, this screen has been a tremendous help. It ensures uniform bean size, which is crucial for roasting. The machine is reliable, easy to clean, and significantly reduces waste.