Introduction

The fertilizer industry plays a crucial role in modern agriculture by supplying essential nutrients that boost crop yields and improve soil health. To meet strict quality requirements and maintain consistent product performance, fertilizer manufacturers rely heavily on accurate particle size control and impurity removal. Vibrating screens are indispensable in this process. Whether it’s urea, NPK, ammonium sulfate, or organic fertilizers, vibrating screening machines ensure that each granule meets the required size specifications, moisture level, and purity standards, enhancing both product quality and production efficiency.

🌿 Additional Section: Handling Special Fertilizer Types

Organic and Bio-Fertilizers

The rise of sustainable agriculture has led to increased use of organic and bio-fertilizers, such as compost, bone meal, and microbial inoculants. These materials often have higher moisture content and irregular shapes, making them more challenging to screen than mineral fertilizers.

- Low-frequency linear vibrating screens or tumbler screens are often used for these products to avoid damaging fragile particles.

- Special anti-blinding mesh cleaning systems, such as ultrasonic or ball-cleaning devices, help maintain throughput.

- Adjusting vibration amplitude and inclination improves the screening of sticky organic matter.

Controlled-Release and Specialty Fertilizers

For coated or controlled-release fertilizers, particle integrity is essential. Screening after coating ensures uniform coating thickness and removes clumps that can affect nutrient release rates. High-precision vibrating screens with gentle motion are preferred to avoid breaking the coating layer.

🌾 Additional Section: Environmental and Safety Considerations

Fertilizer plants face increasing environmental regulations regarding dust control, wastewater, and worker safety. Vibrating screens support compliance in several ways:

- Enclosed screening systems reduce dust emissions during granule classification.

- Integration with dust collection systems minimizes air pollution in production areas.

- Proper screening reduces waste generation by recycling off-size particles.

- Lower noise designs help fertilizer plants meet occupational health standards.

These improvements not only ensure regulatory compliance but also enhance plant sustainability and worker well-being.

⚙️ Additional Section: Maintenance Best Practices for Fertilizer Screening Equipment

Operating vibrating screens in fertilizer production requires careful maintenance due to the corrosive and abrasive nature of materials like ammonium sulfate, urea, and NPK. Best practices include:

- Regular mesh inspections to prevent blinding and maintain accurate particle size classification.

- Corrosion-resistant materials, such as stainless steel or coated frames, extend screen lifespan.

- Lubrication schedules for bearings and motors prevent premature failures in dusty environments.

- Vibration monitoring systems help detect imbalances early, avoiding unplanned downtime.

Proper maintenance not only improves screening performance but also reduces operational costs and increases machine lifespan.

🌍 Additional Section: Global Market Trends and Future Potential

The global fertilizer market is shifting toward precision agriculture and environmentally friendly fertilizers. This evolution creates new opportunities for vibrating screen technology:

- Custom mesh configurations for micro-granular fertilizers used in drip irrigation systems.

- Automated screening lines integrated with real-time particle size analysis.

- Modular screening systems that can adapt quickly to different product grades for export markets.

- Smart control systems that adjust vibration frequency and amplitude automatically based on material flow.

Manufacturers that invest in advanced screening solutions can achieve higher yields, lower energy use, and meet increasingly strict quality standards.

Importance of Particle Size and Purity in Fertilizer Production

In fertilizer manufacturing, the particle size distribution directly affects the dissolution rate, application efficiency, and storage stability of the final product. Oversized particles can cause uneven nutrient distribution in the soil, while fines may lead to caking, dust problems, and inconsistent fertilization. Similarly, the presence of foreign materials—such as stones, packaging fragments, or production residues—can damage equipment and reduce product value. Vibrating screens solve these problems by classifying, separating, and removing impurities with high accuracy.

Applications of Vibrating Screens in the Fertilizer Industry

1. Raw Material Screening

Before production begins, raw materials such as phosphate rock, potash, sulfur, or compost must be screened to ensure uniform particle sizes and remove debris. This improves mixing efficiency and prevents blockages in granulation equipment.

2. Granule Classification After Production

After granulation, fertilizers typically pass through multi-deck vibrating screens that classify products into several size fractions:

- Oversize granules are crushed and recycled back to the granulator.

- Undersized granules are returned for reprocessing.

- On-size granules are sent to coating, drying, and packaging.

This ensures uniform granule size, which is essential for consistent nutrient release and spreading performance.

3. Drying and Cooling Stages

During drying and cooling, vibrating screens are used to prevent agglomeration and remove lumps. This helps maintain free-flowing products and reduces the risk of clogging in downstream equipment.

4. Coating and Final Quality Control

Some fertilizers receive an anti-caking or slow-release coating. After this process, final screening ensures that coated granules meet specifications and that no oversized or irregular particles enter packaging.

Advantages of Vibrating Screens for Fertilizer Processing

- Precise Sizing: Achieves tight size tolerances for uniform nutrient application.

- High Capacity: Handles large production volumes efficiently.

- Versatility: Suitable for granular, powdery, or organic fertilizers.

- Reduced Waste: Oversize and undersize products can be recycled back into the process.

- Improved Product Quality: Ensures clean, uniform granules for packaging and sale.

- Enhanced Plant Efficiency: Prevents equipment blockages and reduces downtime.

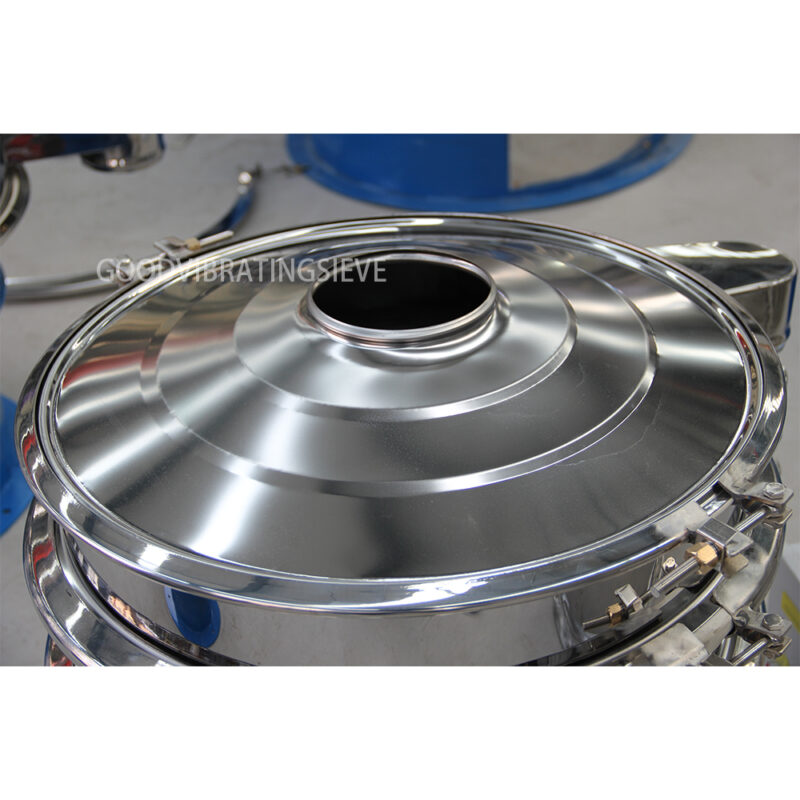

Types of Vibrating Screens Used in Fertilizer Plants

- Linear Vibrating Screens – Ideal for large capacity and precise sizing of granules.

- High-Frequency Screens – Used for fine powder fertilizers or for separating dust.

- Tumbler Screens – Suitable for delicate organic or bio-fertilizers where gentle motion is required.

- Rotary Screens – Commonly used in pre-screening of raw materials or large lumps.

Technological Innovations in Fertilizer Screening

Recent developments are making vibrating screens even more effective for fertilizer producers:

- Modular screen decks allow quick mesh changes for different product sizes.

- Anti-blinding systems prevent mesh clogging during screening of sticky or wet fertilizers.

- Smart monitoring systems enable predictive maintenance and reduce unexpected downtime.

- Energy-efficient drives lower operational costs while maintaining high throughput.

Case Study: NPK Fertilizer Production Line

A fertilizer manufacturer producing 50 tons per hour of NPK granules installed a three-deck linear vibrating screen to classify product sizes. Oversize particles were crushed and recycled, undersize was returned to the granulator, and on-size granules were coated and packaged. This improved product uniformity by 25%, reduced dust by 40%, and increased overall plant efficiency, leading to higher market competitiveness.

Future Outlook

With growing demand for high-efficiency fertilizers and sustainable agriculture, manufacturers are focusing on producing products with precise granule sizes, minimal waste, and consistent quality. Vibrating screens will continue to play a key role in achieving these goals. As smart technologies and environmentally friendly solutions become standard, the fertilizer industry will rely even more on advanced screening equipment to optimize processes and meet regulatory standards.

Conclusion

Vibrating screens are essential equipment in the fertilizer industry, ensuring consistent granule size, purity, and product quality across all production stages. From raw material preparation to final packaging, they enhance efficiency, reduce waste, and improve end-user satisfaction. As the global demand for fertilizers continues to grow, the role of vibrating screening technology will only become more critical in delivering high-quality products to farmers worldwide.