In the highly competitive world of spice production, delivering chili powder that meets international standards of purity, uniformity, and texture is no longer optional—it is essential. Global markets demand spice products that are free from impurities, consistently ground, and visually appealing. As processors strive to eliminate clumps, contaminants, and inconsistencies, cutting-edge screening solutions have become central to production lines. Aman, a trusted name in spice processing machinery, answers this need with its advanced vibrating sieve machine—a technological innovation designed to optimize chili powder quality from the very first screen to the final export-ready batch.

Revolutionizing Spice Purity Through Precision Screening

Chili powder, with its intense aroma and pungent heat, is a staple ingredient in cuisines across the globe. However, beneath its vibrant red hue lies a meticulous production process that determines its quality, uniformity, and purity. In the competitive spice trade, where contamination thresholds are low and consumer expectations are high, producers must leverage advanced technology to maintain a consistent product. Central to this quality assurance is the use of high-efficiency screening systems. Aman, an industry leader in spice processing machinery, has engineered a solution that not only meets these standards—but exceeds them. Their advanced sieve shaker machine is a game-changer for chili powder producers seeking unparalleled performance.

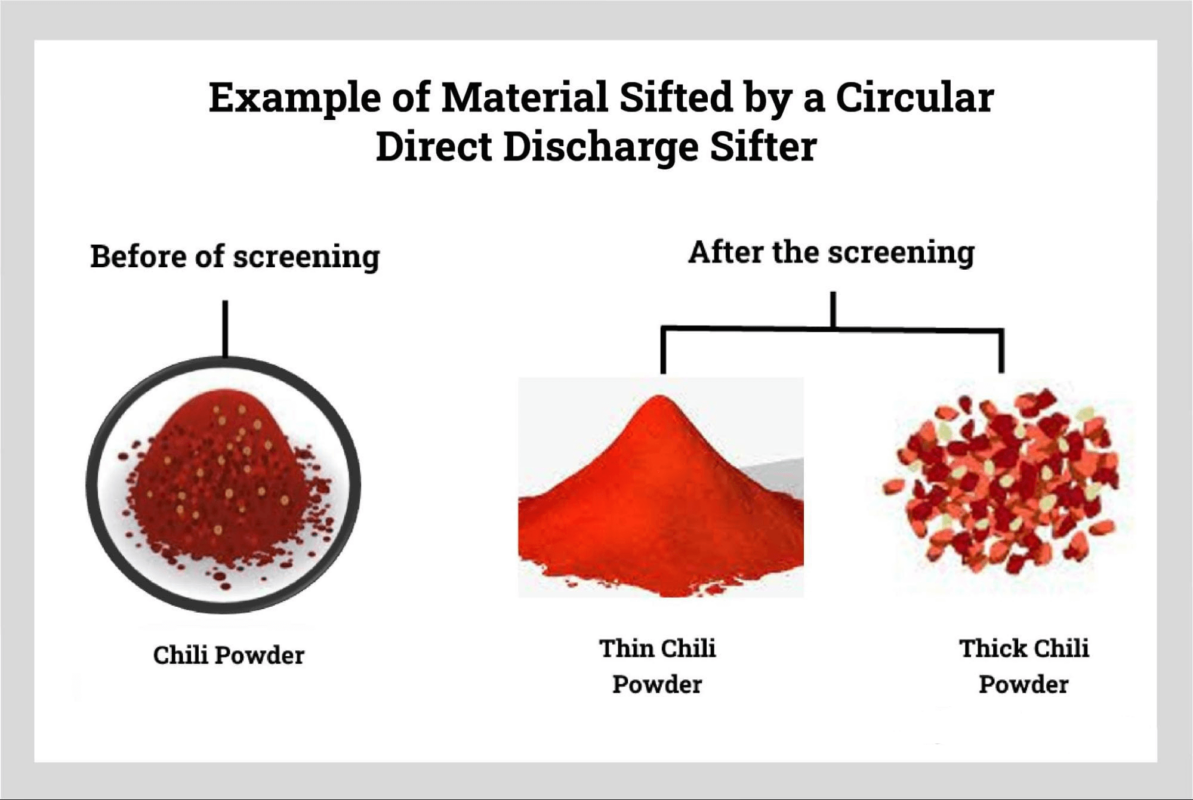

In the world of bulk spice processing, inconsistencies in particle size and the presence of foreign material can degrade product value and pose compliance risks during export. The vibratory technology developed by Aman offers a robust remedy by integrating multi-layered mesh decks and precision-engineered vibrational dynamics. These features enable granular separation based on density, shape, and size, ensuring chili powder batches are not only homogenous but also free of contaminants. The equipment is especially suitable for fine screening during export, where regulatory scrutiny demands a high level of product uniformity and purity.

By deploying this system, manufacturers can effectively screen out lumps and improve uniformity, an essential process that addresses one of the most pervasive challenges in spice processing—moisture-induced agglomeration. Lump formation in chili powder affects flowability, dosage accuracy, and packaging efficiency. With Aman’s vibrating sieve machine, agglomerates are systematically broken down, restoring the powder’s fine texture and optimizing it for downstream applications such as sachet filling, capsule production, or culinary integration. The result is a final product that performs consistently across all usage scenarios, elevating both consumer satisfaction and brand credibility.

Furthermore, the energy-efficient vibratory motors employed in the system ensure prolonged operation without overheating or mechanical degradation. This durability makes Aman’s solution ideal for both small-scale producers and large export-driven operations. Its scalable architecture supports continuous production, reducing downtime and enhancing throughput. The added benefit of low maintenance requirements further positions it as a preferred solution for processors focused on maximizing ROI while delivering premium-grade spice products.

Enhancing Post-Shelling Efficiency and Foreign Material Elimination

Chili powder production begins long before the grinding phase. The post-harvest shelling and preliminary cleaning stages are equally critical, particularly when it comes to ensuring that only high-quality, de-seeded, and debris-free chilies proceed to milling. After shelling, grade and sieve out impurities is not just a procedural step; it is the cornerstone of quality control in spice manufacturing. Foreign particles such as stems, husk fragments, dirt, and even microplastics can compromise the integrity of the final product. Their removal is, therefore, non-negotiable in any serious processing facility.

To tackle this, Aman has designed its commercial sieve machine with a multi-tier classification system that simultaneously separates unwanted particulates while preserving the integrity of the chili particles. This screening machine is equipped with variable mesh sizes, which can be adapted based on raw material specifications and desired end-use. It performs dual functions—grading based on particle dimension and purifying the feed from extraneous contaminants. The precise vibrational frequency and amplitude are adjustable, allowing processors to fine-tune the machine according to the specific characteristics of each chili variety, be it Byadgi, Guntur, Kashmiri, or Cayenne.

A distinctive advantage of Aman’s system lies in its ability to execute continuous batch purification with minimal operator intervention. Sensors embedded in the machinery provide real-time feedback on throughput, impurity concentration, and mesh integrity. This telemetry enables proactive maintenance and instant troubleshooting, reducing unplanned downtimes and material wastage. As a result, manufacturers can uphold stringent food safety standards, especially when producing for markets that adhere to certifications like BRC, FSSC 22000, and USDA Organic.

Another noteworthy feature is the sanitation-oriented design. The contact surfaces of the sieve frames are fabricated from food-grade, corrosion-resistant stainless steel, which inhibits bacterial colonization and supports quick wash-down cycles. With tool-less dismantling and modular assembly, operators can execute rapid cleaning transitions between spice batches, preventing cross-contamination and upholding allergen control policies.

By integrating this machinery into their processing lines, spice manufacturers not only increase product purity but also streamline their operations. The consistent elimination of sub-par material before grinding leads to higher-quality powder, improved grinding efficiency, and better packaging performance. All of these translate to reduced rework, fewer consumer complaints, and elevated brand equity in global markets.

Scalable Technology for Global Spice Commerce

In today’s hyperconnected marketplace, the demand for clean-label, export-grade chili powder has surged dramatically. International buyers—from food conglomerates to specialty retailers—seek traceable, contaminant-free, and visually consistent spices that conform to a growing list of regulatory criteria. The onus is on producers to match these expectations through technology-enabled processing. Herein lies the critical value proposition of Aman’s sieve shaker machine, which is meticulously engineered to function as the linchpin of scalable spice production systems.

Unlike static screening models or outdated rotary sifters, the vibratory platform offered by Aman introduces a harmonized balance of throughput volume and fine separation. The machine’s structural robustness, combined with a highly efficient vibratory mechanism, allows it to handle both coarse and finely ground chili material without clogging or segregation issues. This makes it an ideal investment for facilities looking to process multiple spice types with uniform standards. Its modular design also allows integration with upstream grinders, downstream pneumatic conveyors, and automated bagging systems—enabling a seamless transition from raw input to packaged output.

A critical requirement in the international spice trade is achieving particle size distribution that aligns with buyer specifications. Aman’s system enables micron-level control through customizable mesh configurations and frequency modulation. Whether the target market requires ultrafine chili powder for seasoning mixes or slightly coarse granules for traditional formulations, the machine ensures specification adherence with minimal material loss. Moreover, the fine screening process is especially suitable for fine screening during export, where visual and tactile uniformity can significantly impact buyer perception and contract renewal rates.

Another hallmark of Aman’s innovation is its emphasis on data intelligence. Equipped with industrial IoT capabilities, the machine captures operational metrics such as vibration frequency, product flow rate, and sieve wear levels. These insights can be fed into ERP and quality management systems, providing processors with a real-time view of their production health. With batch traceability becoming a global mandate, this data integration supports not only compliance but also continuous process optimization.

Moreover, the rugged construction of the machine—with its anti-vibration mounts, sealed motor housings, and non-reactive surfaces—ensures long-term durability even under aggressive working conditions. This results in lower total cost of ownership and reduced environmental impact, especially when compared to high-energy legacy machinery. As sustainability metrics increasingly influence buyer decisions, such energy-efficient and durable machinery becomes a silent yet decisive asset for spice exporters.

From boutique spice companies to large-scale agro-industrial firms, the ability to deliver top-tier chili powder is now intertwined with technological sophistication. Through its advanced commercial sieve machine, Aman has given processors a critical edge—enabling them to meet demand surges, comply with evolving regulations, and build trusted global brands rooted in quality and consistency.

Conclusion

In a marketplace where spice purity is both a selling point and a regulatory imperative, the integration of advanced screening technology defines success. With a focus on high-precision separation, contaminant removal, and export-grade consistency, Aman’s suite of solutions—especially its cutting-edge sieve shaker machine and commercial sieve machine—has become the gold standard for chili powder processors worldwide. Whether the goal is to screen out lumps and improve uniformity, grade and sieve out impurities after shelling, or ensure product is especially suitable for fine screening during export, Aman delivers scalable, efficient, and reliable machinery that reshapes what’s possible in spice manufacturing. As global quality demands intensify, only those equipped with such precision technologies will thrive in the future of spice commerce.