How Sand Sieving Machines Enhance Efficiency in Food Factories

Sand sieving machines play an integral role in food factories by ensuring the quality and consistency of ingredients. While sand sieving machines are traditionally associated with construction and mining, their adaptability makes them invaluable in food processing. In food factories, precision is crucial to maintaining safety and efficiency, and these machines provide just that.

The sieving process eliminates impurities, including non-edible particles and irregularly sized materials. This ensures that ingredients like flour, sugar, and grains meet strict quality standards. A reliable sand sieving machine can process large volumes of material quickly, significantly reducing manual labor. This speed translates to lower production costs and higher output, which is critical in meeting industry demands.

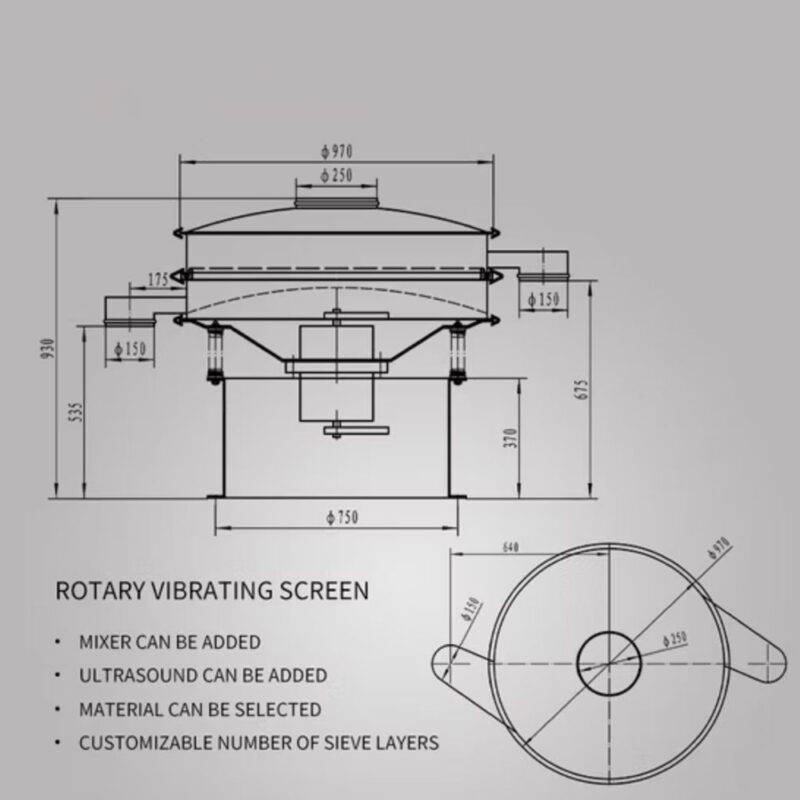

Moreover, sand sieving machines with advanced features like adjustable mesh sizes offer flexibility. Food factories often deal with multiple product lines requiring different sieving specifications. With a single machine capable of handling diverse requirements, factories can streamline operations without investing in multiple devices.

Finally, automation in modern sieving machines minimizes human error, enhancing consistency and compliance with food safety regulations. Features such as self-cleaning mechanisms reduce downtime, allowing factories to maintain a seamless production process.

How Sieving Machines Maintain Purity and Flavor in Spice Processing

For spice manufacturers, maintaining purity and flavor is paramount. Sieving machines are crucial in achieving this by meticulously separating fine particles from contaminants. Whether you’re dealing with turmeric, paprika, or ground pepper, a reliable sieving machine ensures uniform texture and removes foreign elements, enhancing the final product’s quality.

Modern sieving machines equipped with vibration technology excel at removing dust and small debris that could alter the spices’ flavor profile. Additionally, these machines prevent cross-contamination, a significant concern in spice production. By maintaining hygienic sieving conditions, they preserve the authentic taste of spices while ensuring compliance with food safety standards.

The use of sieving machines also improves the overall efficiency of spice processing. Traditional methods often result in uneven particle sizes, which can affect packaging and shelf life. A high-quality sieving machine creates uniform granules or powders, enhancing the visual appeal and functionality of the product.

Lastly, sieving machines with fine mesh options allow for ultra-fine sieving, essential for premium spice blends. Manufacturers can cater to high-end markets with consistent and superior products, all thanks to these precision machines.

Choosing the Right Sieving Machine for Processing Food-Grade Materials

Selecting the right sieving machine is a critical decision for industries handling food-grade materials. Not all sieving machines are created equal, and factors like hygiene, efficiency, and material compatibility must guide the choice.

One of the primary considerations is the machine’s material. Food-grade stainless steel is the industry standard due to its resistance to corrosion and ease of cleaning. Machines made from this material ensure compliance with strict food safety regulations while maintaining durability.

Another vital aspect is the mesh size. Different food-grade materials require varying levels of filtration. For example, fine powders like flour need ultra-fine mesh, while larger grains can pass through coarser sieves. A machine with adjustable mesh sizes offers versatility and ensures you can handle a variety of materials without compromising efficiency.

Ease of cleaning is another factor that cannot be overlooked. Sieving machines designed with quick disassembly features and minimal dead zones allow for thorough cleaning, reducing the risk of contamination. This is especially crucial for factories processing multiple food products, as residue from one batch can impact the next.

Finally, consider advanced features like vibration settings and dust covers. Adjustable vibrations ensure precise separation, while dust covers maintain a clean environment. This combination not only improves operational efficiency but also aligns with strict hygiene protocols. A well-chosen sieving machine becomes an indispensable tool for any industry dealing with food-grade materials.