1. Choosing the Right Separator for Fine and Coarse Spice Particles

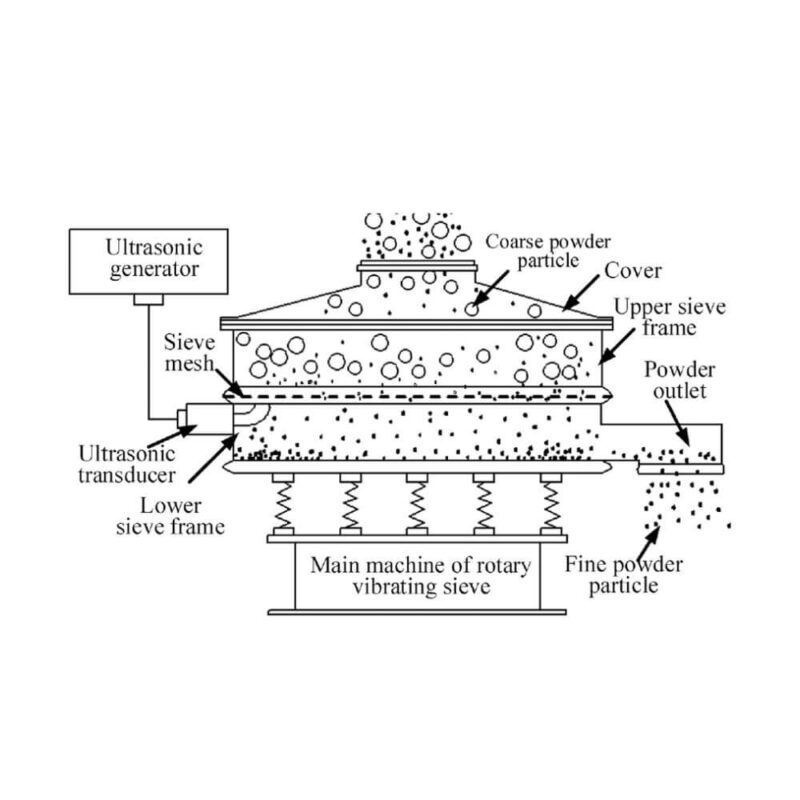

Selecting the correct separator for spice processing is crucial, especially when dealing with a mix of fine and coarse particles. Rotary vibrating screens, with their multi-layered and customizable mesh options, allow spice manufacturers to achieve precise particle separation. For fine powders like ground cinnamon or turmeric, fine-mesh screens ensure that only the desired particle size passes through, maintaining smooth texture and uniformity. Meanwhile, for coarser particles such as crushed pepper or dehydrated herbs, the same machine can be adjusted with larger mesh options, allowing coarse particles to be sifted effectively without clogging.

Rotary vibrating screens support interchangeable mesh sizes and multiple deck configurations, which makes them ideal for spices with mixed particle sizes. By preventing the finer particles from mingling with the coarser ones, manufacturers can control quality, meet industry standards, and achieve a consistent grind. This ability to cater to both fine and coarse particles ensures each spice batch maintains the required purity and granularity, which ultimately impacts flavor and cooking properties in the end product.

2. How Vibration Technology Enhances Spice Quality and Consistency

Vibration technology is at the heart of why rotary vibrating screens are so effective in spice production. Consistent, controlled vibrations help move particles evenly across the screen surface, minimizing buildup and ensuring an even distribution of spices. This vibration action also reduces clogging, which is particularly beneficial when processing sticky or oily spices, such as ginger powder or cloves, that tend to clump or adhere to screening surfaces.

A rotary vibrating screen’s ability to adjust vibration intensity and frequency offers even more control over how spices are separated. Fine tuning these parameters can ensure that every particle meets exact size specifications, which enhances the overall quality of the spice and maintains a consistent particle size across batches. This control over quality and consistency is vital for spice manufacturers who seek to maintain their brand’s reputation for high-grade spices.

Additionally, by controlling particle size distribution through vibration, manufacturers can better preserve the aroma and potency of spices. Consistent particle size also impacts the shelf life of spices, as a uniform grind can reduce the rate of oxidation or flavor loss over time. By enhancing quality and consistency, vibration technology provides a direct path to improved spice preservation, flavor retention, and customer satisfaction.

3. Enhancing Production Speed: The Power of Efficient Spice Separation

Rotary vibrating screens are designed to handle large production volumes without compromising on precision, making them indispensable in high-demand spice manufacturing environments. The circular, multi-directional movement generated by rotary screens ensures that spices are processed quickly and efficiently. By maintaining a consistent flow rate, even during peak production periods, these screens help manufacturers meet high-volume demands without risking product quality.

Efficient separation is especially crucial for spice manufacturers who need to produce large quantities of spices on tight schedules. Unlike traditional screens, which may require frequent maintenance to prevent clogging, rotary vibrating screens reduce downtime thanks to their effective self-cleaning action and easy-to-access mesh layers. The speed and ease with which these machines separate particles contribute directly to productivity, as there’s minimal need for frequent machine adjustments or cleaning interruptions.

Fast separation also aids in batch consistency, allowing for quicker turnover between different spice types. For instance, switching from one spice blend to another, or from coarse to fine grinding, can be done with minimal setup time. With rotary vibrating screens, manufacturers can maximize operational efficiency, reduce labor costs, and maintain a steady production pace. In the competitive spice industry, these time and cost savings can make a significant difference, ensuring products reach the market faster without compromising quality or precision.